Linuo DT Series Knife Gate Valve is mainly intended for process control in pulp slurry, residue discharge and sewage treatment. It is especially suitable for installation with equipment such as stock cleaners, gravity, separators, aqua pulper.

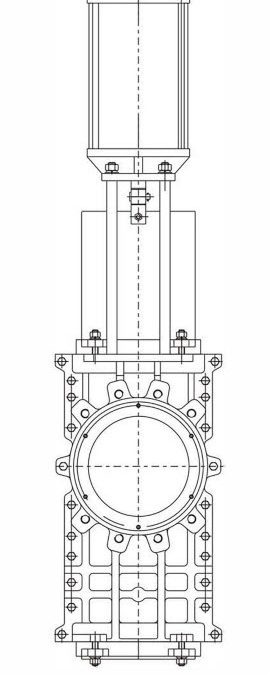

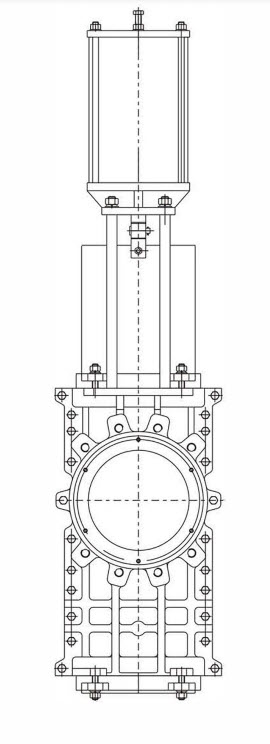

| DT Series Through-Going Knife Gate Valve |

Application

Linuo DT series knife gate valve is mainly intended for process control in pulp slurry, residue discharge and sewage treatment. It is especially suitable for installation with equipment such as stock cleaners, gravity, separators, aqua pulper.

Features

1.Valve is full port in the open position with low flow resistance.

2. Two-piece body construction with no cavities eliminates product build-up.

3. Tight shutoff, reliable performance.

4. O-ring loaded removable seat is self-compensating with good abrasion resistance and long service life.

5. Available with metal seat, PTFE seat or EPDM seat – selection is based on application.

Technical Specifications

Nominal Diameter: DN80-DN600

Nominal Pressure: PN10, PN16, ANSl150

Working Temperature: -29″C-1 OO”C, -29″C-230″C

Air Supply Pressure: 5-7 bar

Bi-Directional: Soft seated valves are bi-directional to 10 bar in the preferred direction with limited tightness at low pressure in non-preferred.

To view more about our DT Series Through-Going Knife Gate Valve click here;

KV Knife Gate Valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with hand wheel, or can be automated with pneumatic cylinder actuator for remote operations The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles, so the knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

Our organisation is committed to achieving excellence in quality performance. KV Controls undertakes all activities in a highly responsible, professional and competent manner and strives to continuously improve performance towards an ultimate objective of zero incidents , failures or complaints together with maximum efficiency and customer satisfaction.

We at KV Controls recognize that Total Cost of Ownership is not only the purchase price but also the cost of operation. Our relentless focus on customer service and streamlining systems are geared to ensure that we live up to our motto: Total Cost of Ownership.

KV Controls will add value to your business, whether you are one of our satisfied customers in the Mining, Chemical, Petro-Chemical or Pulp & Paper industry or a potential buyer. We supply valves for control, on-off or isolation for liquids, steam, gas and slurries. Our KV Controls valve selection software gives us calculated results for selecting the best product for your application.

For more information on our products and services you can contact our Sales Manager on frikkie@kvcontrols.co.za or 063 433 1363