LATEST NEWS

The Ceramic Ball Control Valve

The ceramic lined valve has very good performance on abrasion erosion, and corrosion resistance, and excellent heat-shielding, electric insulation. Mainly used in electric power, petroleum, chemical, metallurgy, mining, sewage treatment and other industrials where the metal valve cannot be applicable.

More About our Knife Gate Valves

KV DQ Knife Gate Valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with hand wheel, or can be automated with pneumatic cylinder actuator for remote operations The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles, so the knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

RB Series Trunnion Mounted Ball Valve

RB Series Trunnion Ball Valve is with fire safe, blow-out proof shaft, anti-static and no emission design. Spring loaded seat design to ensure good tightness under low differential pressure with low operation torque requirement. Special seat design for low temperature or high temperature application is available.

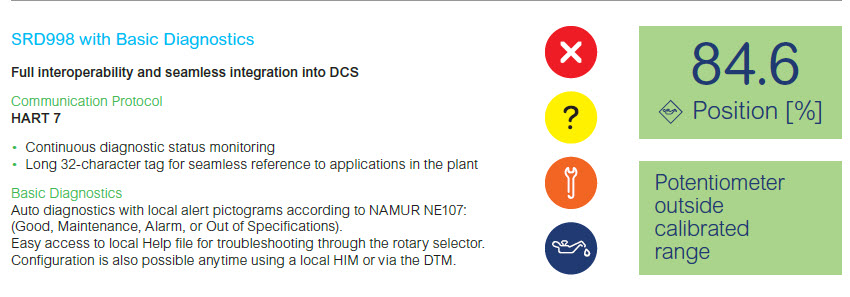

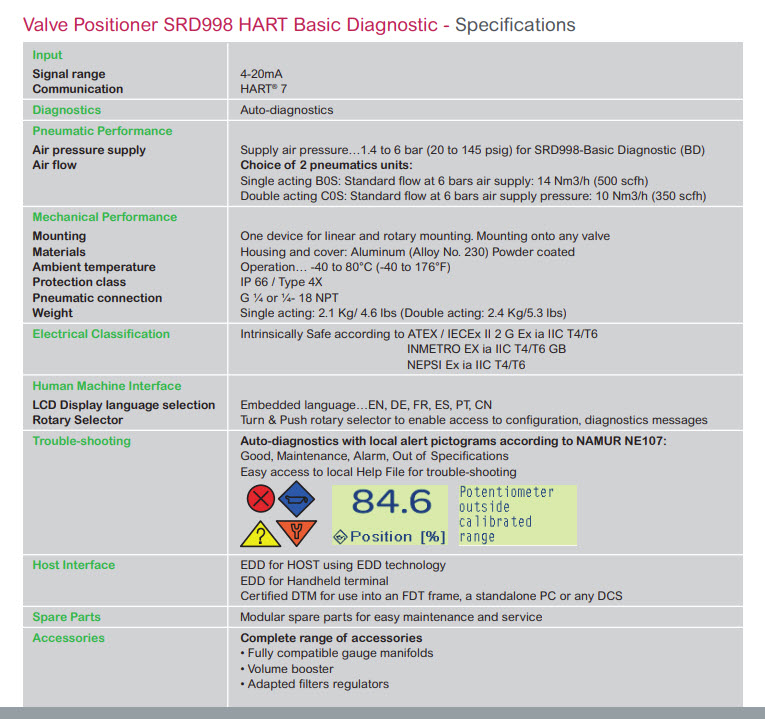

Valve Positioner SRD998 Intelligent Control Basic & Advanced Diagnostics

SRD998 Intelligent Positioner with HART Communication

The intelligent positioner SRD998 is designed to operate pneumatic valve actuators and can be operated from control systems, controllers or PC-based configuration and operation tools such as the FDT/DTMs or VALcare™. The enhanced functionalities of the SRD998 Intelligent Valve Positioner enable a significant reduction in commissioning time and reduction of the total installation cost. The new device offers an improved control performance with or without external accessories such as volume boosters for optimal efficiency of your process. The modular design makes maintenance simpler, and the advanced technology increases the total life time of the device.

Valve Positioner SRD998 Intelligent Control

SRD998 Intelligent Positioner with HART Communication

The intelligent positioner SRD998 is designed to operate pneumatic valve actuators and can be operated from control systems, controllers or PC-based configuration and operation tools such as the FDT/DTMs or VALcare™. The enhanced functionalities of the SRD998 Intelligent Valve Positioner enable a significant reduction in commissioning time and reduction of the total installation cost. The new device offers an improved control performance with or without external accessories such as volume boosters for optimal efficiency of your process. The modular design makes maintenance simpler, and the advanced technology increases the total life time of the device.

KV Controls incorporates unique design with our DK Series Slurry Knife Gate Valve

The DK Series Slurry Valve from KV Controls incorporates a unique design , especially for slurries. The Process are only in contact with the rubber seats which uniquely seal when the valve are open. The stainless steel knife gate only get into contact with the process when the valve closes, once closed there is no flow to damage the gear. The seats can be replaced as a spare part without any special tools required. These 6 pieces DN250 PN10 valves was delivered from stock to a Base Mineral plant . The startup was on time due to fast delivery.

More About Our Plug Valves

Read more about our Lined Plug Valve and Plug Valve. Our Plug Valves are designed and manufactured for the process industries to handle the liquids which contains slurry and sludge or the liquids which are hazardous, corrosive ect. for hard working conditions.

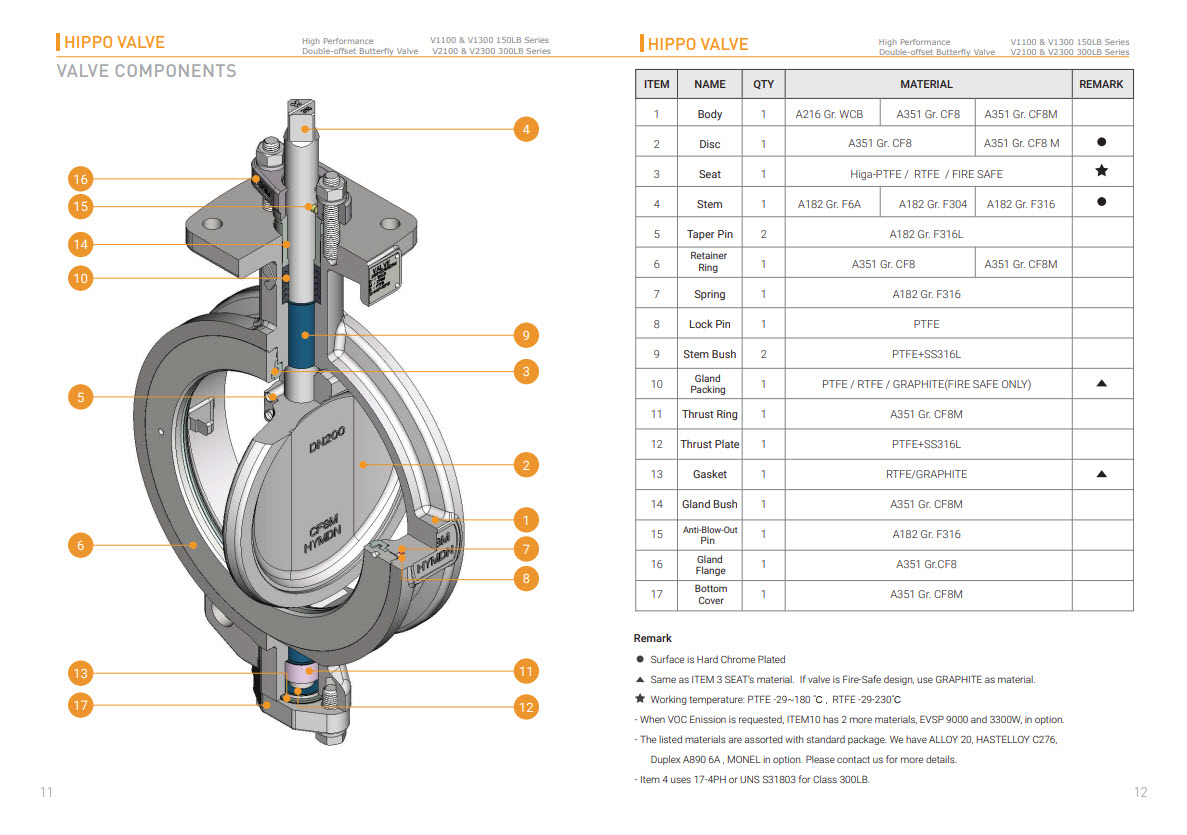

Components of the KVC Double Eccentric High Performance Butterfly Valve

KVC Double Eccentric High Performance Butterfly Valve, is a TUV ISO9001 certified. Our supplier have more than 40 years experience in butterfly valve and other related products, their engineering teams have lots of experience in industries such as chemistry, pulp and paper, petrochemical, air separator, HVAC, energy, power and water treatment plants.

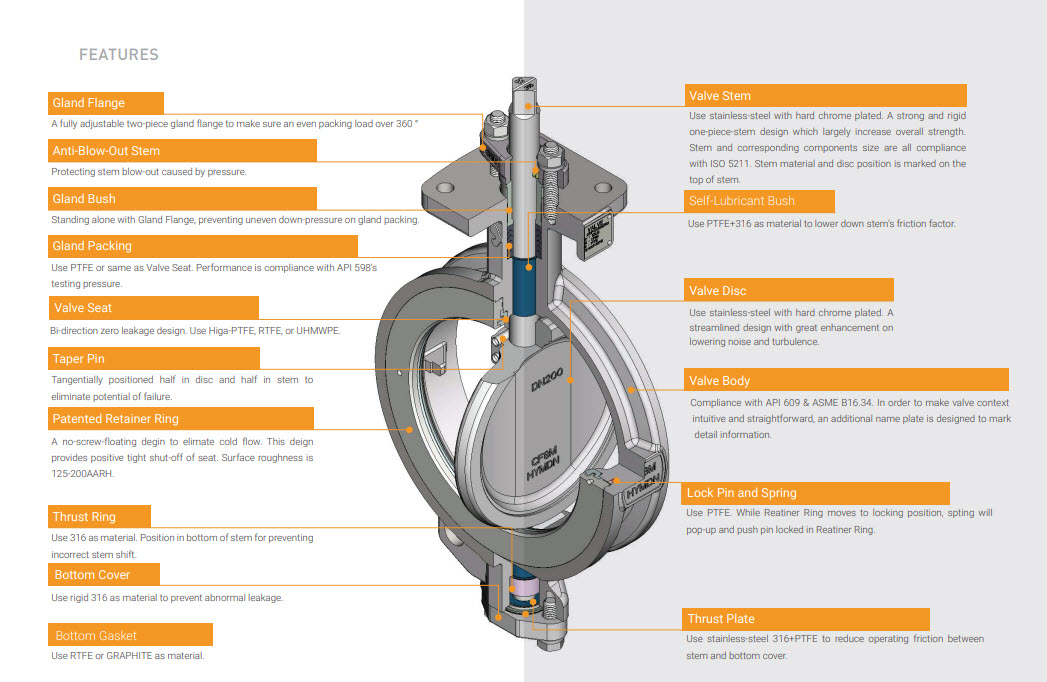

Features of the KVC Double Eccentric High Performance Butterfly Valve

KVC Double Eccentric High Performance Butterfly Valve, is a TUV ISO9001 certified. Our supplier have more than 40 years experience in butterfly valve and other related products, their engineering teams have lots of experience in industries such as chemistry, pulp and paper, petrochemical, air separator, HVAC, energy, power and water treatment plants.

KVC Double Eccentric High Performance Butterfly Valve

KVC Double Eccentric High Performance Butterfly Valve, is a TUV ISO9001 certified. Our supplier have more than 40 years experience in butterfly valve and other related products, their engineering teams have lots of experience in industries such as chemistry, pulp and paper, petrochemical, air separator, HVAC, energy, power and water treatment plants.

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023