Introduction

At KV Controls, we are dedicated to delivering cutting-edge solutions that precisely address your industrial needs. Among our esteemed product offerings, the Lined Butterfly Valves stand out as a pinnacle of innovation in control valve technology. Renowned for exceptional quality, durability, and performance, our impeccably engineered Lined Butterfly Valves set a benchmark in the industry.

Within the intricate realm of industrial valves, one solution has garnered particular acclaim for its distinctive design and versatile applications: the Lined Butterfly Valve. In this blog post, we delve into the origins, nuances, design intricacies, advantages, and key features of the Lined Butterfly Valve. Furthermore, we shed light on its diverse applications and pivotal role across industries in South Africa.

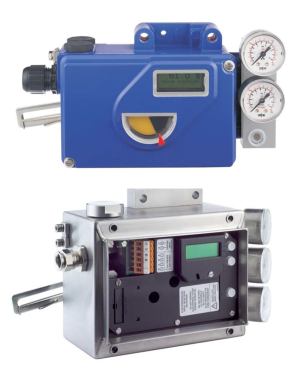

Since the valve port corresponds to the piping diameter, a high flow capacity is guaranteed. It features ease of maintenance, repeatable on-off, long life durability. The concentric design is commonly used in the power generation, brewing, water and food industries and suitable for both gaseous and liquid service. Typically applied in chemical/petrochemical process, food and beverage, and pulp and paper etc.

VIEW SPECIFICATIONS HERE

What is a Lined Butterfly Valve?

A Lined Butterfly Valve is a specialized type of flow control valve that operates with a rotating disk (or “butterfly”) to regulate fluid flow. The valve’s unique design is centered around a disk that can either allow or block the flow of liquids or gases in a pipeline.

What distinguishes Lined Butterfly Valves from conventional butterfly valves is the lining, typically made of PTFE (Teflon), rubber, or other specialized materials. This lining is critical in providing enhanced chemical resistance, reduced friction, and superior durability, making the valve ideal for highly corrosive environments or industries dealing with aggressive fluids.

Key Features of Lined Butterfly Valves:

- Corrosion Resistance: The lining ensures protection against corrosive fluids, making it suitable for industries like chemical processing and wastewater management.

- High Durability: With materials like PTFE, these valves offer exceptional resistance to wear and tear, ensuring longer operational life.

- Low Torque Operation: Designed for ease of operation, Lined Butterfly Valves require minimal force for opening and closing, making them highly efficient.

- Versatile Material Compatibility: Suitable for both liquid and gaseous mediums, offering flexibility in a range of applications.

- Compact Design: Butterfly valves are generally smaller than other valve types, which allows for easy installation and maintenance in tighter spaces.

- Excellent Sealing Capability: The lining contributes to tight sealing, reducing the likelihood of leaks, thus enhancing system safety and efficiency.

Application Scenarios for Lined Butterfly Valves:

- Chemical Processing: Given their resistance to harsh chemicals, Lined Butterfly Valves are essential in chemical plants, where they handle aggressive acids, bases, and solvents.

- Water Treatment Plants: These valves regulate the flow of treated and untreated water, ensuring smooth operation in wastewater and desalination systems.

- Pharmaceutical Industry: Due to their contamination resistance, they are frequently used in the pharmaceutical sector for handling sensitive or hazardous fluids.

- Food & Beverage Industry: Lined Butterfly Valves are ideal for the sanitary handling of beverages and food processing fluids, where contamination control is crucial.

- HVAC Systems: Their efficient control of air and water flow makes them perfect for HVAC systems in large industrial buildings.

- Mining Industry: In South Africa, Lined Butterfly Valves play a critical role in controlling slurry flows and other abrasive fluids in mining operations.

Why Choose KV Controls as Your Supplier?

At KV Controls, we pride ourselves on offering high-quality Lined Butterfly Valves designed to meet the unique challenges of South Africa’s industrial landscape. Our valves undergo rigorous quality checks to ensure they meet both national and international standards. Whether you are in mining, pharmaceuticals, or water treatment, we provide tailored valve solutions that maximize your operational efficiency.

LATEST PRODUCTS

INDUSTRIES

WE

SERVE

Chemical &

Petrochemical

Mining

Industry

Power

Generation

Pulp & Paper

Industry

Steel

Industry

Hydrogen

Industry

Water

Industry

Get in

Touch

KV Controls mission is world class prompt service with business integrity. Our Safety Management System is accredited (certified) to ISO 45001:2018.

OUR TRUSTED BRANDS

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023