Knife Gate Valves: Suppliers In South Africa

At KV Controls, we take pride in providing cutting-edge solutions tailored to meet your industrial requirements. Within our product lineup, the Knife Gate Valve stands as a pinnacle of innovation in control valve technology. We offer impeccably engineered Knife Gate Valves that excel in the industry due to their exceptional quality, durability, and performance.

In the intricate landscape of industrial valves, one particular solution has stood out for its unique design and versatile applications – the Knife Gate Valve. In this blog post, we’ll explore the origin, understanding, design, advantages, and key features of the Knife Gate Valve. Additionally, we’ll shed light on its applications and the industries in South Africa where this valve plays a pivotal role.

The Origin of the Knife Gate Valve

The Knife Gate Valve traces its roots back to the mid-20th century, where it was initially developed to address specific challenges in industries requiring reliable flow control solutions. Over the years, it has evolved into a specialized valve known for its ability to handle slurries, powders, and other challenging media with ease.

Understanding the Knife Gate Valve

The Knife Gate Valve is a linear motion valve used to regulate the flow of fluids, particularly in systems with suspended solids or viscous media. It derives its name from the sharp-edged gate that slices through the media, providing a tight seal when closed and minimal resistance when open.

The Design of the Knife Gate Valve

The design of the Knife Gate Valve is characterized by its simplicity and efficiency. The gate, often made of stainless steel or other durable materials, is operated by a manual handwheel or automated actuator. The unobstructed flow path makes it particularly suitable for applications where clogging is a concern.

Advantages of the Knife Gate Valve

- Bi-Directional Sealing: The Knife Gate Valve offers effective bi-directional sealing, ensuring a secure closure regardless of the flow direction.

- Low Maintenance: Its uncomplicated design results in low maintenance requirements, making it a cost-effective choice for industries looking to minimize downtime.

- High Flow Capacity: The unobstructed flow path and full bore design contribute to high flow capacity, making it ideal for applications involving thick or abrasive media.

Key Features of the Knife Gate Valve

- Sharp-edged Gate: The defining feature, the sharp-edged gate, ensures a tight seal and effective slicing through challenging media.

- Various Actuation Options: Knife Gate Valves can be operated manually or through various automated actuation options, including pneumatic and electric actuators.

Application Scenarios

The Knife Gate Valve finds applications in diverse scenarios, including:

- Wastewater Treatment Plants: Handling sludge and abrasive media efficiently.

- Pulp and Paper Industry: Regulating the flow of pulp, slurries, and other fibrous materials.

- Mining Operations: Managing the flow of abrasive slurries and tailings.

Industries the Knife Gate Valve Can Be Applied

- Mining and Minerals Processing: Ideal for applications involving abrasive slurries and dense media.

- Water and Wastewater Treatment: Suitable for handling sludge and other challenging fluids.

- Pulp and Paper: Used in regulating the flow of pulp, paper stock, and chemical solutions.

Explore our selection of Knife Gate Valves, where we can offer you the optimal solution for every need.

Ceramic Knife Gate Valve

The Ceramic knife gate valve is suitable for corrosive medium with high hardness of particles (such as slag water), or soft particles in pipeline.

Features

Nominal pressure: PN10-PN25

Applicable temperature: <-250 degrees=”” c=”” br=””>Actuator Pressure: 0.6-0.8MPa

It can be designed according to customer’s requirement

DK-Series Slurry Knife Gate Valve

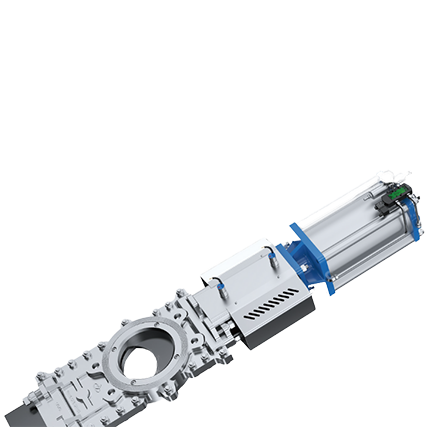

The Lenor DK-Series Slurry Knife Gate Valves are available as manual valves with handwheel or gearbox, or they can be automated with pneumatic cylinders or electric actuators.

Features

Two-piece body without cavity.

With shearing force & auto-cleaning function.

Removable seat provides easy maintenance.

Applications

It is suitable for control systems in industries including mining, chemical, biochemistry, oil and gas, fiber, pharmaceutical industry etc., especially suitable for control of medium containing slurry, stock,fiber, dust and grain etc.

Technical Specification

DN: DN80~DN800

PN: PN10~PN16 ANSI150LB

Connection: Wafer

Temperature℃: -29~100

Sealing: Soft Seat

Tightness Leakage: Class VI

BodyMaterial: (1)WCB (2)CF8 (3)CF8M (4)CF3M

DQ-Series Knife Gate Valve

The Lenor DQ-Series Knife Gate Valves are available as manual valves with handwheel or gearbox, or they can be automated with pneumatic cylinders or electric actuators.

Features

Economical one-piece compact body with shearing force and auto-cleaning function.

Removable seat provides easy maintenance.

Applications

It is suitable for control systems in industries including chemical, biochemistry, pulp & paper, chemical fibre, pharmaceutical, environmental protection etc.

Technical Specification

DN: DN50~DN1200

PN: PN10~ PN16 ANSI150LB

Connection:/Wafer

Temperature℃:-29~100

Sealing:/Metal Seat/Soft Seat

Tightness Class: IV/Class IV

Body Material:(1)WCB (2)CF8 (3)CF8M (4)CF3M

DS-Series Knife Gate Valve

The Lenor DS-Series Knife Gate Valves are available as manual valves with handwheel or gearbox, or they can be automated with pneumatic cylinders or electric actuators.

Features

One-piece compact body with shearing force & auto-cleaning function.

Removable seat provides easy maintenance.

Good wear resistance.

Quick opening and closing.

Applications

It is suitable for high concentration cleaner, weight separator, aquapulper in pulp and paper industry. Especially suitable for control of medium containing stock, fiber, dust and grain etc.

Technical Specification

DN: DN100~DN600

PN: PN10~ PN16 ANSI150LB

Connection: Wafer

Temperature℃:-29~100

Sealing: Metal Seat/Soft Seat

Tightness Leakage: Class IV

Body Material: (1)WCB (2)CF8 (3)CF8M (4)CF3M

DT-Series Knife Gate Valve

The Lenor DT-Series Knife Gate Valves are available as manual valves with handwheel or gearbox, or they can be automated with pneumatic cylinders or electric actuators.

Features

One-piece compact body with shearing force & auto-cleaning function.

Removable seat provides easy maintenance.

Good wear resistance.

Applications

It is suitable for high concentration cleaner, weight separator, aquapulper in pulp and paper industry,especially suitable for control of medium containing stock, fiber, dust and grain etc.

Technical Specification

DN: DN50~DN800

PN: PN10~PN16 ANSI150LB

Connection: Wafer

Temperature℃:-29~100

Sealing: Metal Seat/Soft Seat

Tightness Leakage: Class IV

Body Material: (1)WCB (2)CF8 (3)CF8M (4)CF3M

Conclusion

As we navigate the realm of industrial valves, the Knife Gate Valve emerges as a reliable and efficient solution for industries grappling with challenging media. In South Africa, suppliers play a crucial role in providing high-quality Knife Gate Valves to meet the diverse needs of these industries. Understanding the origins, design, advantages, and applications of the Knife Gate Valve is key to making informed decisions and ensuring seamless operations in the ever-evolving industrial landscape.

For inquiries or assistance regarding our Knife Gate Valves and other industrial solutions, please contact us at sales@kvcontrols.co.za