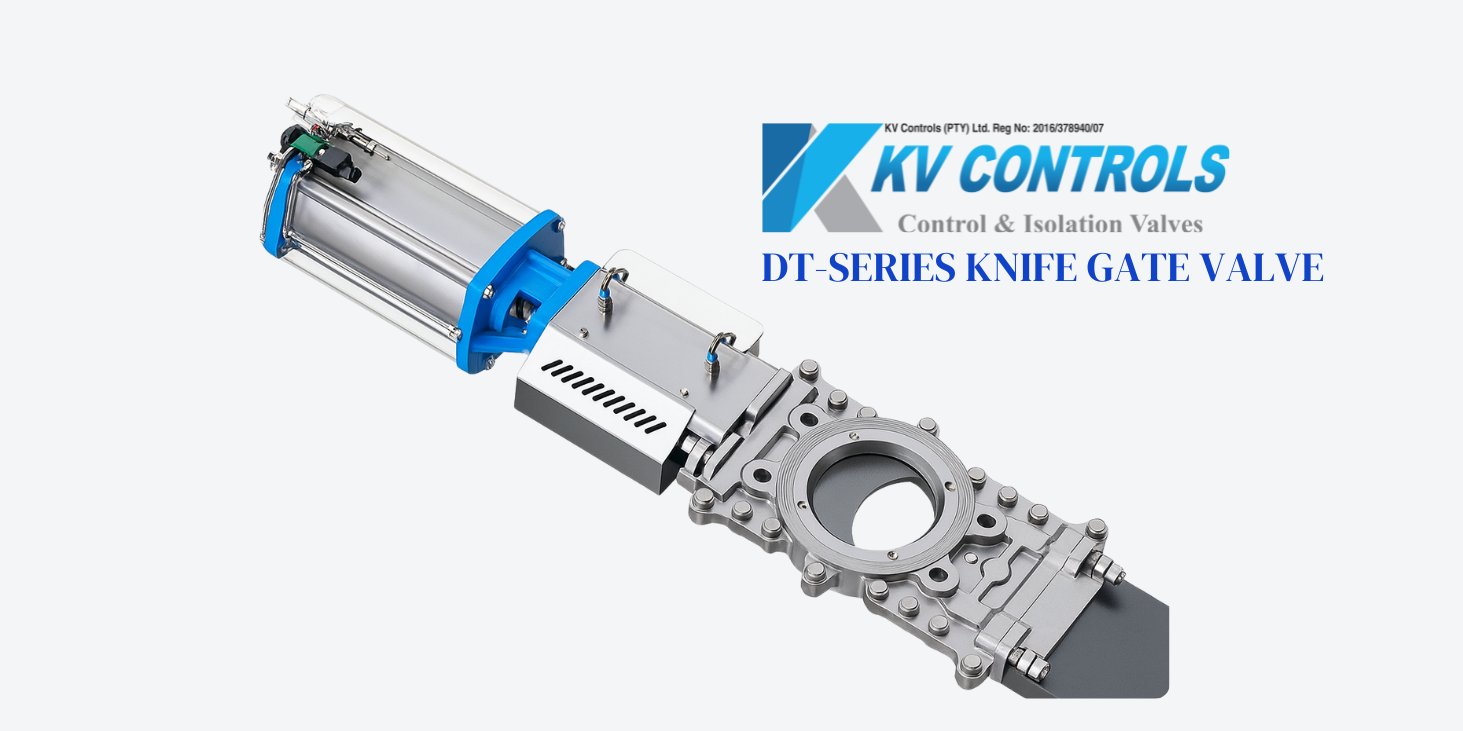

DT-Series Knife Gate Valve: Leading Suppliers in South Africa

At KV Controls, we specialise in reliable, high-performance valve solutions for demanding industrial processes. One of our flagship products is the DT-Series Knife Gate Valve – a robust, low-maintenance valve designed for media that most standard valves struggle with, including slurries, fibres and fluids with high solids content.

As trusted DT-Series knife gate valve suppliers in South Africa, we support plants across key sectors such as pulp and paper, mining, wastewater, chemical processing and more. In this blog, we unpack the design, features, technical specifications and applications of the DT-Series so you can see where it fits in your operation.

What Is a DT-Series Knife Gate Valve?

The DT-Series Knife Gate Valve is an industrial valve designed to handle viscous fluids, slurries and media containing solids. It delivers reliable isolation and control in applications where fibre, stock, dust, grain or abrasive particles would quickly damage or clog conventional valves.

The DT-Series is available as:

-

Manual valves with handwheel or gearbox

-

Automated valves with pneumatic cylinders

-

Electrically actuated valves for full remote or PLC-based control

This makes the DT-Series a versatile solution wherever you need on/off or modulating control in tough process conditions.

Key Features and Benefits of the DT-Series Knife Gate Valve

The DT-Series combines a compact body with a powerful shearing action and easy maintenance design. Core features include:

Compact, Self-Cleaning Body Design

-

Knife-edge gate slices through stock, fibre and solids to prevent clogging.

-

Shearing force and auto-cleaning function help keep the seat and gate clear, reducing build-up and sticking.

Removable Seat for Easy Maintenance

-

Removable seat allows fast replacement without major dismantling.

-

Reduces downtime and long-term life-cycle costs.

Reliable Sealing and Wear Resistance

-

Available with metal seat or soft seat, depending on process media and sealing requirements.

-

Good wear resistance for abrasive or fibre-rich applications.

Full-Bore, Bi-Directional Flow

-

Full port design provides unobstructed flow when open.

-

Bi-directional flow capability offers flexibility in piping layouts.

Multiple Actuation Options

-

Manual (handwheel/gearbox) for simple on-site control.

-

Pneumatic, hydraulic or electric actuators for automation and remote control.

Robust Materials and Corrosion Resistance

-

Body materials:

-

WCB

-

CF8

-

CF8M

-

CF3M

-

-

Engineered for corrosion, erosion and wear resistance in harsh operating environments.

Low Maintenance Design

-

Self-cleaning action and replaceable wear parts support longer service intervals.

-

Ideal where plant uptime and reduced maintenance costs are priorities.

Technical Specifications – DT-Series Knife Gate Valve

Nominal Diameter (DN): DN50 – DN800

Pressure Rating (PN): PN10 – PN16 / ANSI 150LB

Connection Type: Wafer

Operating Temperature: -29°C to 100°C

Seat Options: Metal Seat / Soft Seat

Tightness / Leakage Class: Class IV

Body Materials:

- WCB

- CF8

- CF8M

- CF3M

Core Applications in the Pulp and Paper Industry

The DT-Series Knife Gate Valve is particularly well suited to the pulp and paper sector, where fibrous and thick media are the norm. Typical applications include:

-

High concentration cleaners

-

Weight separators

-

Aquapulpers

-

Lines carrying stock, fibre, dust and grain-rich media

In these duties, the DT-Series offers:

-

Stable shut-off in fibrous pulps

-

Reduced clogging and plugging

-

Longer life under abrasive conditions

Wider Industries and Application Scenarios in South Africa

While the DT-Series is highly effective in pulp and paper, its design also fits many other South African industrial sectors where fluids contain solids, slurry or high viscosity.

1. Mining and Mineral Processing

-

Slurry lines, tailings and process streams with high solids

-

Abrasive, particle-rich media handling

2. Wastewater and Effluent Treatment

-

Sewage, sludge and sediment handling

-

Industrial effluent control and isolation

3. Power Generation

-

Ash slurries and coal-related media in coal-fired plants

-

Auxiliary systems where solids or slurry are present

4. Chemical Processing

-

Corrosive and abrasive chemical slurries

-

Viscous or solids-laden process streams

5. Food and Beverage Processing

-

Fruit pulps, sauces and slurries

-

Wastewater and by-product handling

6. Water and Wastewater Management

-

Municipal water and wastewater networks

-

Industrial pre-treatment and distribution systems

7. Oil and Gas (Upstream and Midstream)

-

Drilling muds and frac fluids

-

Fluids with suspended solids or high viscosity components

8. Steel, Metals, Aggregate and Cement

-

Slag, fines, aggregates and cement slurry control

-

Harsh, abrasive services where wear resistance is critical

In all these scenarios, the DT-Series Knife Gate Valve delivers reliable isolation, reduced clogging and longer service life – helping to keep South African plants running efficiently.