The Ceramic Ball Valve Explained: Functionality, Applications, and Problem-Solving Benefits

Ceramic ball valves are a game-changer in industrial flow control systems. Designed to handle the most abrasive and corrosive substances, these valves outperform their traditional counterparts in demanding environments. In this blog, we’ll delve into what makes ceramic ball valves unique, how they function, the industries that use them, and the common problems they solve.

What is a Ceramic Ball Valve?

A ceramic ball valve is a high-performance valve made from advanced ceramic materials. The key components—including the ball, seat, and sometimes the entire valve body—are constructed from durable ceramics like alumina or zirconia. These materials are known for their:

- Extreme Hardness: Resistant to abrasion and wear.

- Corrosion Resistance: Ideal for handling aggressive chemicals.

- Thermal Stability: Withstands high temperatures and thermal cycling.

- Longevity: Extended service life compared to metal valves.

The valve operates like a traditional ball valve, with a spherical disc (the ball) controlling the flow of liquids or gases. The difference lies in the superior properties of ceramic materials, making them ideal for extreme applications.

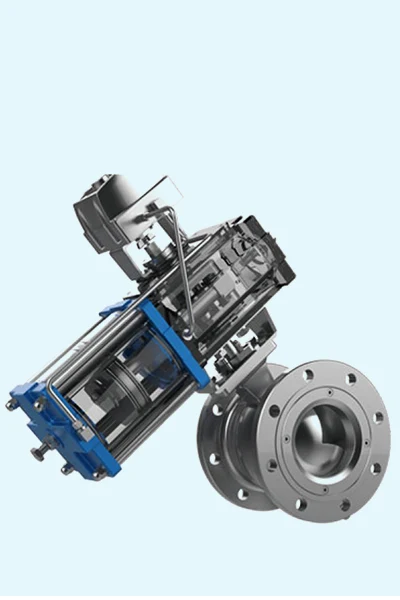

How Does a Ceramic Ball Valve Work?

Ceramic ball valves function by rotating a ceramic ball with a hole through its center. When aligned with the pipeline, the hole allows flow; when rotated 90 degrees, the ball blocks the flow. The precision-engineered ceramic surfaces create a tight seal, minimizing leakage and enhancing performance in:

- High-pressure systems

- High-temperature environments

- Abrasive or corrosive applications

The durability of ceramics ensures the valve maintains its integrity even in the harshest conditions, making it a preferred choice for industries facing extreme challenges.

Industries That Use Ceramic Ball Valves

Ceramic ball valves find applications across various industries, particularly where abrasive and corrosive substances are present. Key sectors include:

- Mining and Minerals:

- Handling slurries, ore concentrates, and abrasive particulates.

- High durability reduces downtime and maintenance costs.

- Chemical Processing:

- Managing aggressive acids, alkalis, and solvents.

- Resistant to chemical attack, ensuring safety and longevity.

- Power Generation:

- Used in coal-fired plants, gas turbines, and ash handling systems.

- Withstands high temperatures and erosive ash particles.

- Petrochemical and Oil & Gas:

- Transporting crude oil, natural gas, and refinery by-products.

- Prevents wear and corrosion caused by sand, grit, and chemical exposure.

- Water and Wastewater Treatment:

- Effective in systems with high solid content or chemical dosing.

- Longevity reduces operational costs.

- Pulp and Paper:

- Handling abrasive pulp slurries and chemicals used in processing.

Common Problems Solved by Ceramic Ball Valves

Ceramic ball valves are specifically designed to tackle problems that plague traditional valve systems. Some of the most common issues they address include:

- Abrasion and Erosion:

- In industries like mining, traditional metal valves quickly wear out due to abrasive slurries. Ceramic ball valves resist wear, extending service life.

- Corrosion:

- Chemical industries often face valve degradation from aggressive acids and alkalis. Ceramic materials provide superior resistance to chemical attack.

- Leakage:

- Precision ceramic components create tight seals, reducing leaks and enhancing efficiency in critical processes.

- High-Temperature Degradation:

- Metals can warp or degrade under extreme heat. Ceramics retain their properties even at elevated temperatures, making them ideal for power generation and petrochemical applications.

- Frequent Maintenance:

- The wear resistance of ceramics significantly reduces maintenance requirements, minimizing operational disruptions.

- Cavitation and Noise:

- High-pressure drops can cause cavitation, damaging valves and increasing noise levels. Ceramic ball valves mitigate these effects, ensuring smoother operation.

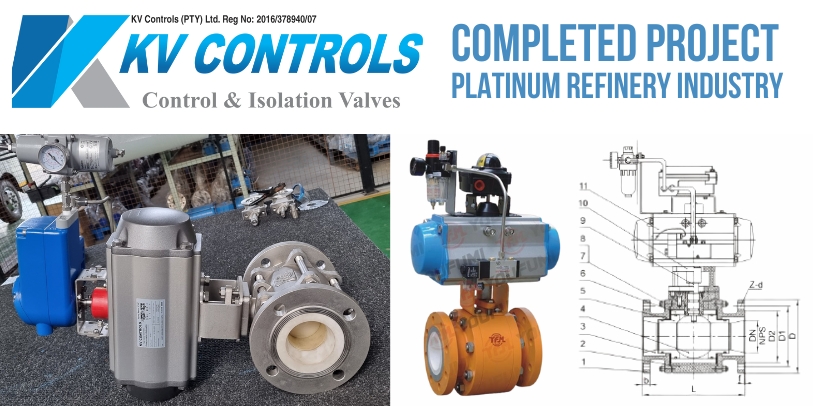

Why Choose KV Controls for Ceramic Ball Valves?

At KV Controls, we specialize in providing high-quality ceramic ball valves tailored to your industry’s needs. Here’s why we stand out:

- Extensive Expertise: Our team understands the unique challenges faced by industries using ceramic ball valves and offers customized solutions.

- Wide Product Range: We stock a variety of ceramic ball valves suitable for diverse applications.

- Commitment to Quality: Our valves meet stringent quality standards, ensuring reliability and performance.

- Customer Support: From selection to installation and maintenance, we provide end-to-end support for your operations.

Conclusion

Ceramic ball valves are the ultimate solution for industries dealing with abrasive, corrosive, and high-temperature environments. Their superior performance, durability, and problem-solving capabilities make them an indispensable choice in various applications.

Partner with KV Controls for reliable ceramic ball valve solutions that keep your operations running smoothly. Contact us today to learn more or to request a quote!