MORE ABOUT

PFA LINED DIAPHRAGM VALVE

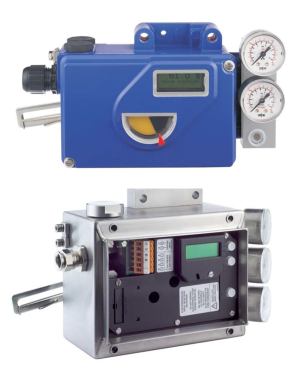

DESCRIPTION

The applicable temperature for lined diaphragm control valve is.29ᵒC-70ᵒC since the pneumatic diaphragm and piston are rubber parts, they are easily hardening and brittle under low temperature,and aging accelerates under high temperature.

This valve is better for vertical installation; if not allowed, consider adding a support bracket for slanting installation.

VIEW SPECIFICATIONS HERE

Understanding the Function of PFA Lined Diaphragm Valves

In industries where aggressive chemicals, high temperatures, and high purity applications are the norm, choosing the right valve is crucial. One such valve that has gained prominence for its versatility and durability is the PFA lined diaphragm valve. But what exactly is a PFA lined diaphragm valve, and what makes it so valuable in various industrial applications? Let’s delve into its function and benefits.

What is a PFA Lined Diaphragm Valve?

A PFA (Perfluoroalkoxy) lined diaphragm valve is a type of valve designed to control the flow of liquids and gases. It consists of a valve body, a diaphragm, and an actuator. The key feature of this valve is the PFA lining, which provides exceptional chemical resistance and purity. PFA is a fluoropolymer with similar properties to PTFE (Teflon), but with added flexibility and transparency, making it ideal for use in harsh chemical environments.

Functionality of PFA Lined Diaphragm Valves

The primary function of a PFA lined diaphragm valve is to regulate the flow of corrosive or high-purity fluids. Here’s how it works:

- Flow Control: The valve regulates flow by varying the area through which the fluid can pass. The diaphragm, typically made of a flexible elastomer, moves up and down to open or close the valve. This movement is controlled by the actuator, which can be manual, pneumatic, or electric.

- Corrosion Resistance: The PFA lining inside the valve body and on the diaphragm provides a highly resistant barrier against corrosive chemicals. This ensures that the valve can handle aggressive acids, bases, and solvents without degrading or contaminating the fluid.

- Purity Maintenance: In industries such as pharmaceuticals and food processing, maintaining high purity is crucial. PFA’s non-reactive nature ensures that the valve does not leach contaminants into the process fluid, maintaining its purity.

- Temperature Resistance: PFA lined diaphragm valves can operate effectively in a wide temperature range, typically from -60°C to 260°C. This makes them suitable for processes involving extreme temperatures.

- Leak Prevention: The diaphragm creates a hermetic seal, preventing any leakage of the process fluid. This is particularly important in applications where even minor leaks can lead to safety hazards or product contamination.

Applications of PFA Lined Diaphragm Valves

Thanks to their robust design and chemical resistance, PFA lined diaphragm valves are used across various industries:

- Chemical Processing: For handling corrosive chemicals and solvents.

- Pharmaceuticals: Where maintaining high purity and avoiding contamination is critical.

- Food and Beverage: For processing fluids that require stringent hygiene standards.

- Water Treatment: In systems that deal with aggressive water treatment chemicals.

- Semiconductors: In processes that demand ultra-high purity to avoid damaging sensitive components.

Advantages of PFA Lined Diaphragm Valves

- Durability: The PFA lining significantly extends the valve’s lifespan, even in aggressive environments.

- Versatility: Suitable for a wide range of applications, thanks to their chemical and temperature resistance.

- Safety: Leak-proof design ensures safe operation, reducing the risk of hazardous spills.

- Low Maintenance: PFA lined diaphragm valves require minimal maintenance due to their robust design and resistance to corrosion.

Conclusion

PFA lined diaphragm valves are essential components in many industrial applications, offering unmatched chemical resistance, purity, and durability. Their ability to handle aggressive chemicals, maintain high purity, and operate across a wide temperature range makes them invaluable in sectors such as chemical processing, pharmaceuticals, food and beverage, water treatment, and semiconductors. By choosing PFA lined diaphragm valves, industries can ensure safe, efficient, and reliable control of their fluid processes.

LATEST PRODUCTS

INDUSTRIES

WE

SERVE

Chemical &

Petrochemical

Mining

Industry

Power

Generation

Pulp & Paper

Industry

Steel

Industry

Hydrogen

Industry

Water

Industry

Get in

Touch

KV Controls mission is world class prompt service with business integrity. Our Safety Management System is accredited (certified) to ISO 45001:2018.

OUR TRUSTED BRANDS

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023