RV series is quarter turn control valve mainly recommended for throttle service, segment ball valve combines globe valve control with the efficiency of a rotary ball valve.

Segment Ball is in V-notch design with strong cutting force and self-cleanness, especially suitable for control of medium containing fiber and tiny solids. Segment Ball Valve was from pulp and paper industry. By research and development the segment ball valve is extended to other industrial such as petrochemical, petroleum, chemical, fiber, power, metallurgy, pharmacy, environmental protection etc.

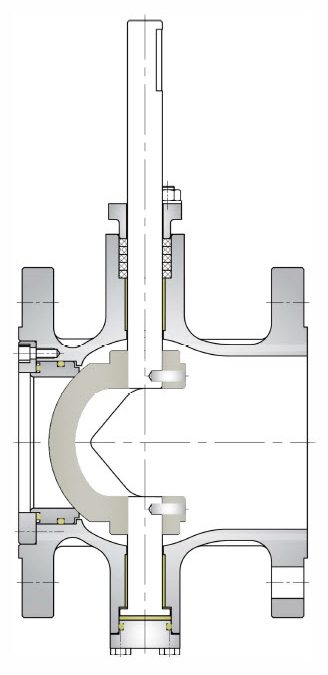

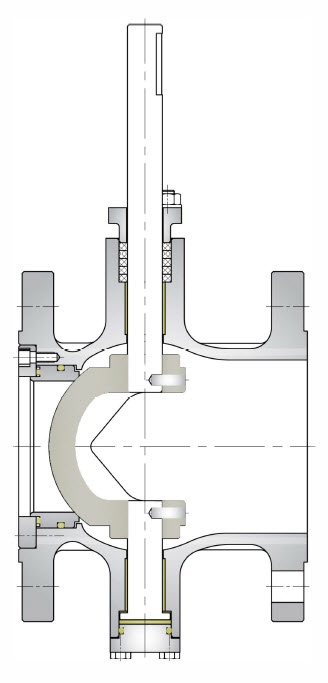

Herewith a breakdown and explanation on how the segmented ball valve is compiled and operates;

FEATURES

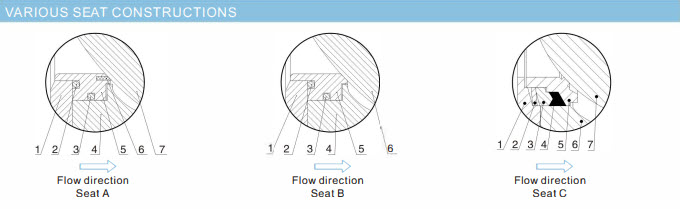

Precise contouring of the V-notch provides excellent control characteristics for an extensive variety of flow applications. Splined connection between t h e shaft and ball ensures precise control and low hysteresis. Detachable seat retainer design provides easy access to trim parts of valves through inlet of valve by simply removing the screws of retainer. therefore, easy maintenance is ensured which saves user lots of costs as seat spares can be kept instead of changing the entire valve body. Superior trunnion bearing technology is engineered for excellent abrasion resistance. Rugged self-adjusting metal seated option is ideally suited for high temperature applications or slurries. Spring loaded seat maintains constant contact with the ball, giving enhanced sealing performance. Shearing action between ball and seal promotes smooth ,non-clogging operation-perfect for fiber or slurry application.

TECHNICAL DATA

End Connection: Wafer DN25 through DN250/1″ through 1 O” , MFR standard.

Flanged DN25 through DN700 I 1″ through 28″ ,

Face to face dimension standard: IEC/DIN534-3-2 or ISA S75.04

Nominal Pressure Rating: 1.0, 1.6, 2.5, 4.0, 6.4(MPa), ANSI 150, ANSI 300,ANSl600

Working Temperature: -20-160″c I -20 -320F,

Optional: -20-230″c I -20 -446°F,

-20-350″c/-20-660 F

Pressure Test: Each Linuo valve undergoes hydraulic test with 1.5 X pressure rating as shell test, and seat tightness test according to ANSI/FCI 70.2.

Leakage: Soft Seat: ANSI/FCI 70.2 Class VI.

Metal Seat: Maximum allowable leakage equal to 1 % of maximum allowable leakage of ANSI/FCI 70.2 Class IV.

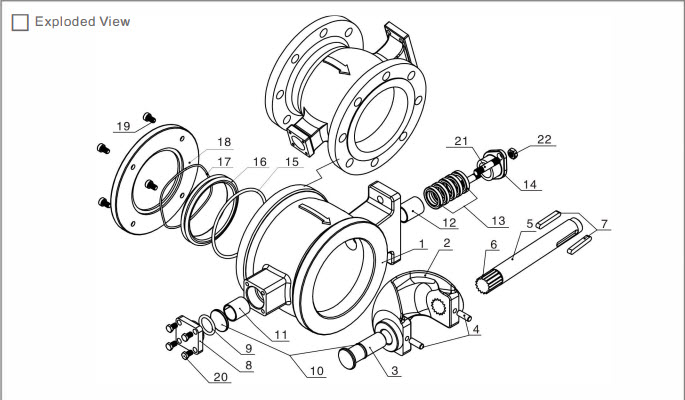

EXPLODED VIEW

VARIOUS SEATED CONSTRUCTION

To view our DATASHEET on the RV Segmented Ball Valve click here;

For more information on placing orders, after care and maintenance services you can contact our Sales Manager on frikkie@kvcontrols.co.za or 063 433 1363

Our organisation is committed to achieving excellence in quality performance. KV Controls undertakes all activities in a highly responsible, professional and competent manner and strives to continuously improve performance towards an ultimate objective of zero incidents , failures or complaints together with maximum efficiency and customer satisfaction.

We at KV Controls recognize that Total Cost of Ownership is not only the purchase price but also the cost of operation. Our relentless focus on customer service and streamlining systems are geared to ensure that we live up to our motto: Total Cost of Ownership.

KV Controls will add value to your business, whether you are one of our satisfied customers in the Mining, Chemical, Petro-Chemical or Pulp & Paper industry or a potential buyer. We supply valves for control, on-off or isolation for liquids, steam, gas and slurries. Our KV Controls valve selection software gives us calculated results for selecting the best product for your application.