What Are PCD Measurements and Why They Matter

PCD, or Pitch Circle Diameter, is a key measurement in mechanical engineering and valve installations. At KV Controls, we often encounter questions about PCD when supplying control valves, actuators, and accessories. Whether you’re dealing with flanges or custom assemblies, understanding PCD ensures proper alignment, secure fittings, and efficient operations.

Let’s explore what PCD is, why it’s important, and how KV Controls ensures precision in every component we supply.

1. What Is PCD?

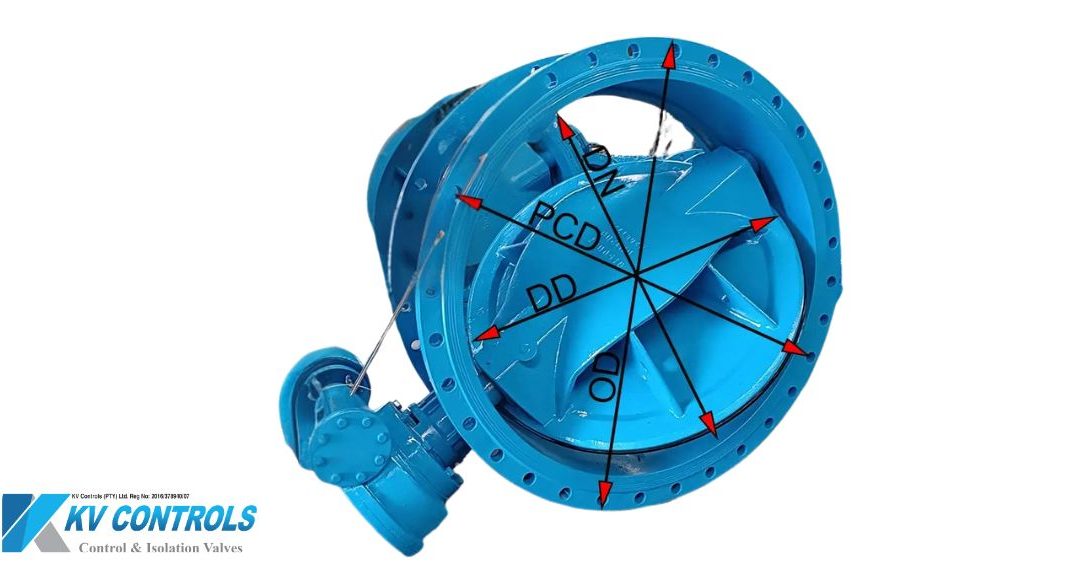

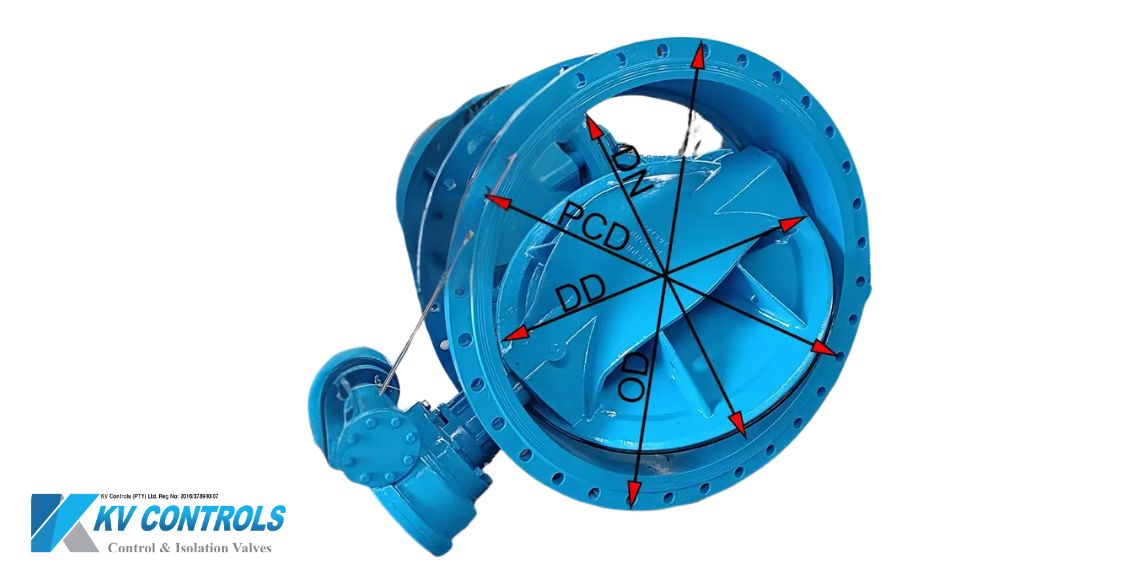

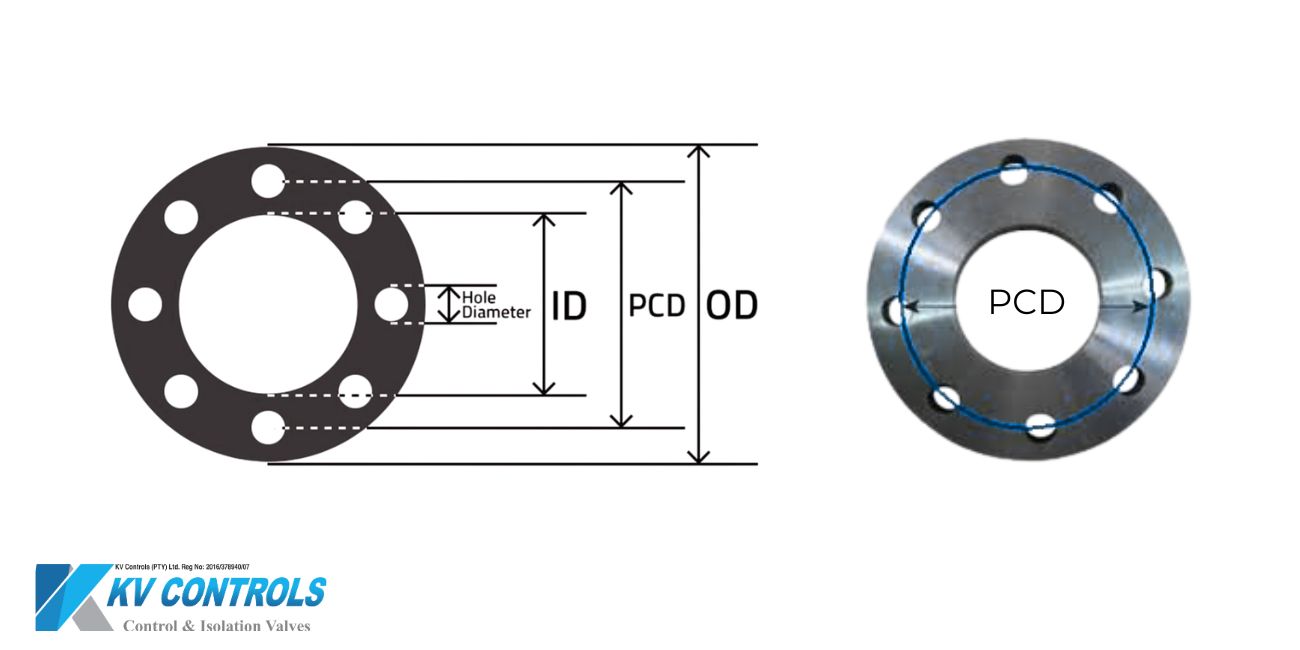

PCD stands for Pitch Circle Diameter. It refers to the diameter of an imaginary circle that goes through the center of all the bolts in a flange or a mounted component.

In a 4-bolt pattern, for example, you measure from the center of one bolt to the center of the bolt directly across, and that’s your PCD. For a 5- or 6-bolt pattern, it’s calculated by measuring between two non-adjacent holes and applying a formula or using specialized PCD tools.

2. Why PCD Is Critical in Industrial Applications

Incorrect PCD measurements can lead to:

-

Misalignment of valve or actuator fittings

-

Uneven load distribution

-

Leaks and mechanical failures

-

Costly downtime

In industries where precision and reliability are non-negotiable—like mining, petrochemical, and water treatment—correct PCD measurements are vital for ensuring operational safety and efficiency.

At KV Controls, we ensure our products match exact PCD requirements, reducing the risk of on-site mismatches and installation delays.

3. How to Measure PCD

For Even Bolt Patterns:

-

4, 6, or 8 bolts: Measure from the center of one bolt to the center of the bolt directly opposite. That’s your PCD.

For Odd Bolt Patterns:

-

Use a specialized PCD calculator or measure between adjacent holes and apply a formula.

Pro Tip: Always use a digital caliper or measuring tape for high accuracy, and double-check against the manufacturer’s specifications.

4. PCD in Valve and Actuator Compatibility

PCD affects how valves, actuators, and mounting kits fit together. That’s why we carefully match actuator flanges, valve patterns, and bracket designs at KV Controls.

Whether you’re installing a Schneider Electric SRD998 Positioner or a Segmented Ball Valve, precise PCD alignment is critical. Our expert team verifies all specs before shipment to ensure everything fits seamlessly.

5. Trust KV Controls for Flange and Mounting Precision

With decades of experience in process control equipment, KV Controls supplies:

-

Custom brackets and mounting kits

-

Valve and actuator assemblies

-

Expert PCD consultation

We work with leading brands and supply equipment across South Africa and Africa, always prioritizing accuracy and client satisfaction.

Final Thoughts

Understanding and applying correct PCD measurements is essential in mechanical installations. KV Controls ensures that every product shipped is compliant with industry standards and your system’s unique requirements.

Need help matching an actuator to a valve or ensuring your flange pattern is compatible? Contact us today for expert assistance and tailored solutions.