Understanding Face-to-Face Valve Dimensions

When working with industrial valves and piping systems, one term that often comes up is “face-to-face dimension.” While it may sound simple, this measurement plays a critical role in ensuring proper installation, flow efficiency, and long-term maintenance in any industrial setup. At KV Controls, we supply high-quality valves with standard face-to-face measurements to guarantee system compatibility and seamless integration.

What is Face-to-Face Dimension?

The face-to-face (F2F) dimension refers to the distance between the two gasket sealing faces of a valve that connects to the pipe flanges. This measurement ensures that the valve fits correctly between two pipeline flanges without the need for adjustments or modifications.

Standard F2F dimensions allow valves from different manufacturers to be interchangeable within the same pipeline.

Why Face-to-Face Dimensions Matter

1. Standardization Across Systems

Face-to-face dimensions are regulated by international standards such as:

-

ASME B16.10 (American)

-

ISO 5752 (International)

-

EN 558 (European)

These standards help ensure that valves of the same type and pressure class can be swapped or replaced without changing the piping.

2. Streamlined Piping Design

Knowing the F2F measurement helps piping engineers design systems with accurate spacing and alignment. This reduces the need for trial-and-error on-site and speeds up installation.

3. Interchangeability of Valves

If you’re replacing an older valve, a new valve with the same F2F dimension will slot in perfectly—saving time and reducing downtime in critical systems.

4. Proper Flow and Function

Correct face-to-face alignment supports proper flow through the valve. Poor spacing can lead to mechanical stress or leaks, particularly in high-pressure systems.

5. Cost Efficiency in Maintenance

Standardized dimensions simplify maintenance and replacements. Technicians can plan ahead, order the correct parts, and reduce labor time during installations.

Common Valve Types and F2F Standards

Each valve type has its own typical F2F standards

Valve Type F2F Standard (ASME B16.10 Example)

Gate Valve Long Pattern (e.g., 4″ = 229 mm)

Globe Valve Longer due to seat design

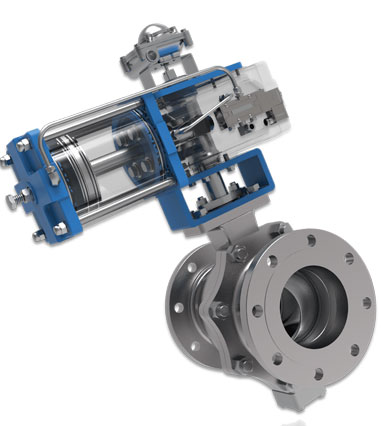

Ball Valve Compact or Full Port – varies

Butterfly Valve Often wafer or lug type (shorter F2F)

Short Pattern vs. Long Pattern Valves

-

Short Pattern (Wafer-Type Valves)

Designed to fit into tight spaces, typically seen in butterfly valves. -

Long Pattern (Full Body Valves)

Matches traditional F2F standards and is ideal when future maintenance or replacement is expected.

Both options have their place, and choosing the right one depends on space availability, pressure requirements, and application.

Trust KV Controls for Your Valve Needs

KV Controls offers a wide range of industrial valves that comply with international face-to-face standards. Whether you’re designing a new system or replacing old components, we ensure your valves are compatible, durable, and ready to perform.

Need help selecting the right valve? Visit our blog on Segmented Ball Valves or contact our team for expert advice.

Final Thoughts

The face-to-face dimension is more than just a number—it’s the foundation for compatibility and efficiency in any valve installation. By understanding and applying standard F2F measurements, you reduce risk, downtime, and costs in industrial environments.

Explore our full range of industrial valves at KV Controls and let our expert team help you build smarter systems from the ground up.