SEGMENTED BALL VALVE: SUPPLIER IN SOUTH AFRICA

At KV Controls, we pride ourselves on delivering top-tier solutions to meet your industrial needs. Among our range of products the Segmented Ball Valve, a pinnacle of innovation in control valve technology. We deliver top-of-the-line segment ball valves engineered to perfection. Our Segment Ball Valves, stand out in the industry for their high quality, durability, and performance.

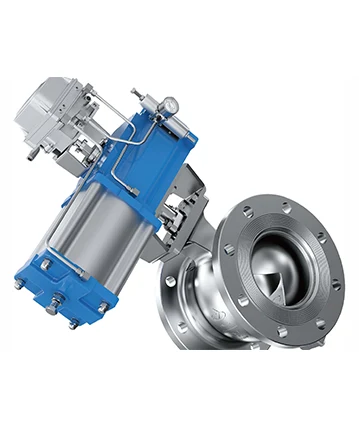

UNVEILING THE RV SERIES: PERFORMANCE

The RV series epitomizes excellence in quarter-turn control valves. Tailored for throttle service, the Segmented Ball Valve seamlessly integrates the precision of a globe valve with the efficacy of a rotary ball valve.

UNDERSTANDING SEGMENT BALL VALVES

Segment Ball Valves are a critical component in various industrial processes, offering precise control over fluid flow. Our Segment Ball Valves feature a robust construction comprising 316 Stainless Steel, ensuring exceptional corrosion resistance and longevity. Customers have the flexibility to choose between Stellite seat or PTFE Seat options based on their specific requirements.

DESIGN INGENUITY: V-NOTCH PRECISION

At the heart of the Segmented Ball Valve lies its V-notch design, meticulously crafted to deliver robust cutting force and self-cleansing capabilities.

ORIGIN AND EVOLUTION: FROM PULP TO POWER

Originating in the pulp and paper industry, the Segmented Ball Valve has undergone a remarkable evolution through relentless research and development efforts. Today, its application extends far beyond its initial niche, finding indispensable utility in petrochemical, petroleum, chemical, fiber, power generation, metallurgy, pharmaceutical, and environmental protection sectors.

ADVANTAGES AT A GLANCE

- Precise Control: The Segmented Ball Valve offers precision in flow control, ensuring optimal performance even in the most demanding applications.

Versatility: Its adaptability across diverse industries underscores its versatility, making it a cornerstone of efficiency in varied operational contexts.

Robust Construction: Engineered with durability in mind, the Segmented Ball Valve boasts robust construction, guaranteeing longevity and reliability in service.

TECHNICAL SPECIFICATIONS

Material: Stainless steel, Carbon steel, Alloy steel

Pressure Rating: ANSI Class 150 – 300, PN 10 – 40

Size Range: 1″ – 24″ (DN 25 – DN 600)

Temperature Range: -196°C to 400°C

APPLICATION SCENARIOS

The versatility of Segment Ball Valves makes them indispensable across various industries. From petrochemical plants to water treatment facilities, our valves find application in controlling the flow of liquids, gases, and slurries with utmost precision. Their ability to withstand high-pressure environments and harsh operating conditions makes them a preferred choice for critical processes.

PETROCHEMICAL INDUSTRY

In the petrochemical sector, where precision and reliability are paramount, the Segmented Ball Valve shines as a beacon of performance. From regulating fluid flow in refining processes to managing critical operations in petrochemical plants.

PHARMACEUTICAL SECTOR

In pharmaceutical manufacturing, where stringent quality standards govern every facet of production, the Segmented Ball Valve emerges as an indispensable asset. Its ability to maintain precise control ensures adherence to exacting specifications, safeguarding product integrity and regulatory compliance.

ENVIRONMENTAL PROTECTION

Segmented Ball Valve rotary movement ensures longevity in packing wear reducing leaking to zero, safeguarding our environment. Whether in wastewater treatment plants or pollution control systems, its efficiency and reliability contribute to the preservation of our planet’s ecological balance.

Industries

Segmented valves are also available in a variety of trim configurations for use in a wide variety of industries including:

• Pulp & Paper

• Sugar & Ethanol

• Refining Process Control

• Power Plants

• Process Control

• Food & Beverage

• Solvent Extraction

• Mining

• Water & Wastewater

• Oil & Gas

• Chemical

• Gas Collection Fields

KEY FEATURES OF SEGMENTED BALL VALVES

Our Segment Ball Valves are available in both Wafer and Flanged configurations, catering to diverse installation needs. Whether it’s ANSI150/PN16 or ANSI 300/PN40 pressure ratings, our valves are engineered to meet the highest industry standards. The inclusion of a Bare Shaft design enhances versatility, allowing for customization and integration with different actuation systems.

ADVANTAGES OF CHOOSING KV CONTROLS SEGMENT BALL VALVES

Unmatched Durability: Crafted from high-grade materials and precision-engineered, our Segment Ball Valves offer long-term reliability even in demanding environments.

Precise Control: With a segmented ball design, our valves ensure precise control.

Minimal Maintenance: Built for minimal downtime, our valves require little maintenance, reducing overall operational costs and enhancing productivity.

Compliance and Certification: Our Segment Ball Valves adhere to stringent quality standards and are backed by relevant certifications, ensuring compliance and peace of mind for our customers.

UNDERSTANDING V-PORT SEGMENT BALL VALVES

WHAT IS V-PORT SEGMENT BALL VALVE?

V-Port Segment Ball Valves are a specialized type of quarter-turn valve designed for precise flow control. Their unique V-shaped port and segmented ball construction allow for exceptional cutting force and self-cleaning capabilities. These features make them particularly suitable for handling media containing fibers and small solids.

KEY FEATURES:

Quarter Turn Valve: V-Port Segment Ball Valves operate on a simple yet effective quarter-turn mechanism, facilitating quick and precise adjustments in flow.

Robust Construction: Constructed from high-grade materials such as Stainless Steel 316 (CF8M), these valves offer durability and corrosion resistance, ensuring reliable performance in diverse industrial environments.

Versatile Applications: From pulp and paper industries to chemical plants, oil refineries, power generation facilities, and more, V-Port Segment Ball Valves find applications across various sectors requiring precise flow control.

APPLICATIONS OF V-PORT SEGMENT BALL VALVES

PULP AND PAPER INDUSTRY:

In pulp and paper manufacturing processes, the handling of fibrous media presents unique challenges. V-Port Segment Ball Valves excel in such environments, thanks to their self-cleaning design and ability to withstand the abrasive nature of pulp slurries.

CHEMICAL PROCESSING:

Chemical plants demand precision control, ensure safety and product quality. V-Port Segment Ball Valves offer the reliability and accuracy required for throttling corrosive chemicals and abrasive slurries.

OIL AND GAS SECTOR:

In oil and gas extraction, refining, and distribution, V-Port Segment Ball Valves play a crucial role in regulating fluid flows, controlling process variables, and ensuring operational efficiency in diverse applications.

POWER GENERATION:

Power plants rely on precise flow control to optimize energy production and maintain operational stability. V-Port Segment Ball Valves provide the necessary precision and reliability for regulating steam, water, and other fluids in boiler systems, turbine control circuits, and cooling water networks.

MATERIALS AND CUSTOMIZATION OPTIONS

MATERIAL OPTIONS:

Stainless Steel 316 (CF8M): Standard material offering excellent corrosion resistance and durability.

WCB, Alloy 2205 (Duplex), Alloy 20, 904L, Titanium: Available as per specific requirements, catering to diverse industrial applications.

CUSTOMIZATION:

In addition to standard configurations, V-Port Segment Ball Valves can be customized with special coatings on the ball to enhance performance and longevity in challenging operating conditions.

CONCLUSION

V-Port Segment Ball Valves represent the pinnacle of precision and reliability in flow control technology. With their robust construction, versatile applications, and customizable features, these valves offer unparalleled performance across a wide range of industries. Whether in pulp and paper processing, chemical manufacturing, oil and gas production, or power generation, V-Port Segment Ball Valves stand as the trusted choice for demanding control applications.

For inquiries or assistance regarding V-Port Segment Ball Valves and other industrial solutions, please contact us at sales@kvcontrols.co.za

IN CONCLUSION, THE SEGMENTED BALL VALVE STANDS AS A TESTAMENT TO INGENUITY AND ENGINEERING EXCELLENCE. AT KV CONTROLS, WE INVITE YOU TO EXPERIENCE THE TRANSFORMATIVE POWER OF THE SEGMENTED BALL VALVE, WHERE CONTROL MEETS EFFICIENCY IN PERFECT HARMONY.

MORE INFO

What is a Segmented Ball Valve?

A Segmented Ball Valve is a specialized variation of the conventional ball valve design, distinguished by a contoured V-notch segment within the ball mechanism. This type of control valve offers superior rangeability, precise control, and reliable shutoff capabilities. The V-notch ball configuration facilitates positive shearing action, resulting in an inherent equal percentage flow characteristic. Notably, it ensures non-clogging operation and accommodates high capacity flow control. Engineers have meticulously contoured the V-notch ball to optimize capacity, prolong seal life, and enhance shutoff integrity, making it a preferred choice for various industrial applications.

How It Works

Common Applications

Commonly employed in various industries, V-notch ball control valve bodies excel in regulating erosive or viscous fluids, as well as paper stock or other slurries laden with entrained solids or fibers. These specialized valve designs find indispensable utility in sectors such as the paper industry, chemical plants, sewage treatment plants, the power industry, and petroleum refineries.

Valve Components

The ingenious design of the two-piece shaft in segmented ball valves facilitates an expanded center flow path, ensuring efficient fluid control. This design comprises a drive shaft linked to one side of the segmented ball and a follower shaft connected to the opposite side. Through rotation of the drive shaft, the ball adjusts its position, unveiling a flow path via the V-notch mechanism. This unique configuration offers a significant advantage by accommodating a wide flow range, characterized by a small flow area during minimal travel and a large flow area at maximum travel.

Segmented ball valves are offered with two distinct body end connections: flangeless and flanged, providing flexibility to suit diverse installation requirements.

Moreover, a comprehensive range of metal and soft ball seal materials is available, enabling customization to meet specific application demands with precision and reliability.

Expanded Outlet Version

The expanded outlet variant of the V-notch ball valve is tailored to accommodate enlarged downstream piping configurations. Distinguished by an outlet flange that is one standard line size diameter larger than the inlet, this specialized design is meticulously crafted to effectively manage medium consistency fiber slurries.

Erosive Slurry Control

The slurry variant of the V-notch ball valve incorporates erosion-resistant trim components meticulously engineered to safeguard the valve body from erosive wear. Crafted from high-chromium iron, the body liner, V-notch ball, and flow ring collectively ensure robust protection against erosive flow conditions. Additionally, for applications requiring even greater resistance to aggressive slurry services, an optional ceramic flow ring insert is available, further enhancing the valve’s durability and performance.

Checkout our download section to read more about: Lenor-RV-Series-Segmented-Ball-Valves