LATEST NEWS

KV Controls: Revolutionizing Valve Solutions in South Africa

ISO45001:2018 Certification: A Milestone in Workplace Safety KV Controls proudly announces its ISO45001:2018 certification, an internationally recognized standard for occupational health and...

OUR ACCREDITED State-of-the-Art Repair Centre-Excellence You Can Rely On

KV Controls: Leading the Valve Revolution in South Africa When it comes to industrial valve solutions in South Africa, KV Controls leads the way with unmatched expertise and innovative...

Premium Supplier of the Triple Eccentric Butterfly Valve in South Africa

Exploring the Triple Eccentric Butterfly Valve: Features, Functions, and Applications The Triple Eccentric Butterfly Valve is a game-changer in industrial valve technology, known for its...

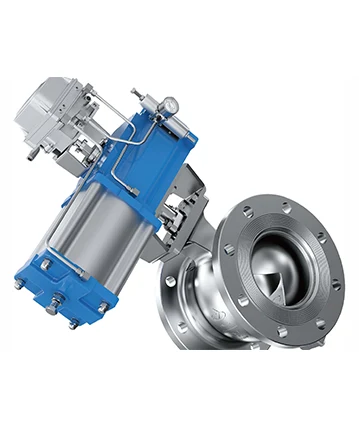

Segmented Ball Valve Supplier in South Africa – KV Controls

Segmented Ball Valve Supplier in South Africa – KV Controls When it comes to precision flow control, KV Controls stands as a trusted name in South Africa. Among our exceptional range of control...

DK-Series Knife Gate Valve: Trusted Suppliers in South Africa

DK-Series Knife Gate Valve: Trusted Suppliers in South Africa At KV Controls, we specialize in providing advanced industrial solutions tailored to meet the unique demands of various industries....

Premium Supplier of Schneider Valve Positioner SRD998 Intelligent Control

Unlocking Precision Control with the Schneider Valve Positioner SRD998: A KV Controls Essential In modern industrIial systems, precision and reliability in valve positioning are critical for...

KV Controls: Premium Supplier of the Globe Control Valve

KV Controls: Preferred Supplier of Globe Control Valves in South Africa. KV Controls: Your trusted supplier of high-quality Globe Control Valves in South Africa. Offering precise flow control...

KV Controls: Preferred Supplier of Lined Ball Valves in South Africa

KV Controls: Preferred Supplier of Lined Ball Valves in South Africa KV Controls is the trusted supplier of Lined Ball Valves in South Africa, known for delivering high-quality,...

We are a Supplier of Copes-Vulcan Desuperheater in South Africa

KV Controls: Preferred Supplier of Copes-Vulcan Desuperheaters in South Africa As a leading provider of industrial valve and control solutions, KV Controls is the preferred supplier of...

AOX Quarter Turn Electric Actuator Supplier in South Africa

Introduction At KV Controls, we are dedicated to delivering cutting-edge solutions that precisely address your industrial needs. Among our esteemed product offerings, the AOX Quarter Turn...

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023