The DK Series Slurry Valve from KV Controls incorporates a unique design , especially for slurries. The Process are only in contact with the rubber seats which uniquely seal when the valve are open. The stainless steel knife gate only get into contact with the process when the valve closes, once closed there is no flow to damage the gear. The seats can be replaced as a spare part without any special tools required. These 6 pieces DN250 PN10 valves was delivered from stock to a Base Mineral plant . The startup was on time due to fast delivery.

Linuo DK Series Knife Gate Valves are soft sealing linear shut off valves that are light weight with compact construction and convenient to install and use. Valves are full port in design to realize the characteristic of small flow resistance. When the gate is open.it will achieve direct current between valve and pipeline. Valves are available as manual with handwheel, or can be automated with actuator for remote operation. The cone-shape design of the gate provides strong cutting force. The die-casting rubber seat which can realize bi-directional sealing. The biggest characteristic of valves is that when they are fully open, the medium will not come into the valve chest, which can prevent the valve chest from settling pulp during the valve running online, then reducing maintenance cost.

KV Controls completed this project at a Base Mineral Plant.

More about our DK Series Slurry Knife Gate Valve

DESIGN FEATURES

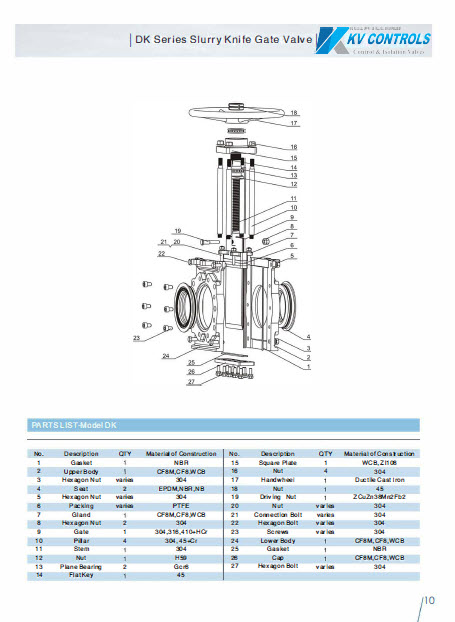

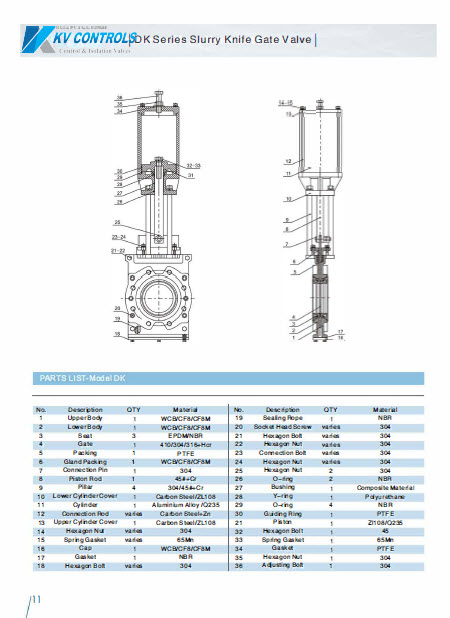

Gate

The arc shape design of the gate provides strong cutting force.Each gate is precision ground and hard chrome plated as a standard.It provides superior abrasion and corrosion resistance.

Internal Packing

Packing gland and packing are internally located which realizes stable sealing and easy online maintenance.

Valve Body

Body is two piece design that is light weight and compact.The body is designed without any cavities, so there is no place for solids to accumulate. With this design, even with high solids content in the slurry, the valve will not jam.

Sealing Seat

Resilient and abrasion resistant rubber seat are die cast in a unique rubber mould, and have a metal support ring to extend the life of the valves. Seat material options are NBA, EPDM and Nature! Rubber.

Bottom Discharge Cover

The bottom discharge cover can easily be removed for routine cleaning. Customer can also outfit the valve with their own purge system.

Technical Specifications

1.Nominal Diameter: DN50-DN600

2.Flange connection as per: ANSI 816.5

3.Valve design and manufacture as per: MSS SP-81

4.Material standard: ASTM A351, A216, etc.

5. Seat tightness testing pressure:2.8Bar and maximum

allowable working differential pressure

(1 0.3bar for size .;.DN600 / 24″ ,6.9bar for size> DN600/24″)

7.Air supply pressure: 4-7 bar

8.Connection Type: Lugged

9.Working Temperature: NBR: -20-+120’C; EPDM : -20-+120’C;

Nature I Rubber : -20-+ 70’C;Viton : -20-+200’C

10.Applicable Media: Pulp, Slurry, Water

11.Leakage: Zero Leakage

To ORDER your DK Series Slurry Knife Gate Valve Contact us Today.

To view more about our DT Series Through-Going Knife Gate Valve click here;

KV Knife Gate Valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with hand wheel, or can be automated with pneumatic cylinder actuator for remote operations The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles, so the knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

Our organisation is committed to achieving excellence in quality performance. KV Controls undertakes all activities in a highly responsible, professional and competent manner and strives to continuously improve performance towards an ultimate objective of zero incidents , failures or complaints together with maximum efficiency and customer satisfaction.

We at KV Controls recognize that Total Cost of Ownership is not only the purchase price but also the cost of operation. Our relentless focus on customer service and streamlining systems are geared to ensure that we live up to our motto: Total Cost of Ownership.

KV Controls will add value to your business, whether you are one of our satisfied customers in the Mining, Chemical, Petro-Chemical or Pulp & Paper industry or a potential buyer. We supply valves for control, on-off or isolation for liquids, steam, gas and slurries. Our KV Controls valve selection software gives us calculated results for selecting the best product for your application.

For more information on our products and services you can contact our Sales Manager on frikkie@kvcontrols.co.za or 063 433 1363