KV Controls Supplier of the LENOR TRUNNION MOUNTED BALL VALVES Range: Elevating Industrial Excellence

At KV Controls, our commitment to excellence extends to every valve solution we offer. Among our premium offerings, the LENOR Valve Range stands out as a pinnacle of engineering precision and reliability. Let’s explore why the LENOR Trunnion Mounted Ball Valves are the go-to choice for industrial applications:

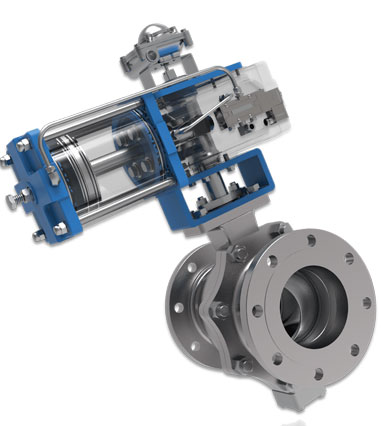

1. LENOR TRUNNION MOUNTED BALL VALVES

RB series is a two-piece body, trunnion mounted ball valve. It is designed as per API6D and fire tested as per API6FA, applicable for various applications in oil and natural gas industry.

TECHNICAL SPECIFICATIONS

Specifications

Nominal Diameter: DN50-DN700, 2”-28”

Pressure Rating: PN10-PN100, Class150-1500

Face-to-face Dimension

End Connection: RF Flanged

End Dimension: ASME B16.10

Leakage Class

ANSI/FCI70.2-2006 Class IV/100

ANSI/FCI70.2-2006 Class V

ANSI/FCI70.2-2006 Class VI

ISO5208 Rate D

ISO5208 Rate A

API 598

LENOR Trunnion Mounted Ball Valves are a type of industrial valve that are designed to control the flow of fluids, such as liquids or gases, in a pipeline. They are called “trunnion mounted” because the ball within the valve is supported by trunnions, which are small shafts that extend from the valve body.

The main function of a trunnion mounted ball valve is to provide a tight shut-off and control the flow of fluids. They are commonly used in applications where high pressure, high temperature, or large flow rates are involved. The trunnion mounted design allows for increased durability and reliability, making them suitable for demanding industrial environments.

Some of the key industries that use trunnion mounted ball valves include:

- Oil and Gas: Trunnion mounted ball valves are widely used in the oil and gas industry for various applications, such as pipeline transportation, refining, and storage. They can handle high-pressure and high-temperature conditions, making them suitable for oil and gas exploration and production.

- Petrochemical: Trunnion mounted ball valves are also commonly used in the petrochemical industry for controlling the flow of various chemicals and gases. They are suitable for handling corrosive and hazardous substances.

- Power Generation: Trunnion mounted ball valves are used in power plants for controlling the flow of steam, water, and other fluids in the power generation process. They are designed to withstand high-pressure and high-temperature conditions.

- Water and Wastewater Treatment: Trunnion mounted ball valves are used in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are designed to handle abrasive and corrosive substances.

- Mining: Trunnion mounted ball valves are used in the mining industry for controlling the flow of various fluids, such as water, chemicals, and slurries. They are designed to withstand harsh and abrasive conditions.

Overall, trunnion mounted ball valves are versatile and widely used in various industries where reliable and efficient flow control is required.

The trunnion mounted design of ball valves offers several benefits compared to other types of valve designs. Here are some of the key advantages:

-

Increased Durability: Trunnion mounted ball valves are designed to handle high-pressure and high-temperature conditions, making them more durable and reliable. The trunnion support system provides additional stability to the ball, reducing the risk of deformation or damage under extreme operating conditions.

-

Enhanced Sealing Performance: The trunnion mounted design allows for the use of larger and more robust sealing elements, such as O-rings or seat rings. This improves the sealing performance of the valve, ensuring a tight shut-off and minimizing the risk of leakage.

-

Improved Flow Control: Trunnion mounted ball valves offer excellent flow control capabilities. The full bore design allows for unrestricted flow through the valve, minimizing pressure drop and turbulence. The ball is also designed to provide a smooth and precise rotation, allowing for accurate flow modulation.

-

Lower Operating Torque: The trunnion mounted design reduces the operating torque required to open or close the valve. This is because the trunnions support the weight of the ball, reducing the friction between the ball and the valve body. As a result, trunnion mounted ball valves are easier to operate and require less energy.

-

Versatility: Trunnion mounted ball valves can be used in a wide range of applications and industries. They are suitable for handling various fluids, including liquids, gases, and slurries. The robust design and materials used in trunnion mounted ball valves make them suitable for demanding environments, such as oil and gas, petrochemical, and power generation.

-

Maintenance Friendly: Trunnion mounted ball valves are designed for easy maintenance. The trunnion support system allows for easy access to the ball and seat for inspection, repair, or replacement. This reduces downtime and maintenance costs.

Overall, the trunnion mounted design offers improved durability, sealing performance, flow control, and ease of maintenance, making it a preferred choice for many industrial applications.

Common maintenance practices for trunnion mounted ball valves include:

-

Regular Inspection: Regular visual inspections should be conducted to check for any signs of wear, damage, or leakage. This includes inspecting the valve body, ball, seats, seals, and stem for any signs of corrosion, erosion, or mechanical damage.

-

Lubrication: Proper lubrication is essential for the smooth operation of trunnion mounted ball valves. Lubrication helps reduce friction and wear between the ball and seats, as well as the stem and packing. Lubrication should be performed according to the manufacturer’s recommendations using the appropriate lubricant.

-

Cleaning: Trunnion mounted ball valves should be cleaned periodically to remove any debris, scale, or deposits that may accumulate on the ball, seats, or body. This can be done by flushing the valve with a suitable cleaning solution or using mechanical cleaning methods.

-

Seat Replacement: Over time, the seats of trunnion mounted ball valves may wear out or become damaged. If leakage is detected or if the valve fails to provide a tight shut-off, the seats may need to be replaced. This should be done following the manufacturer’s instructions and using compatible replacement parts.

-

Stem Packing Replacement: The stem packing of trunnion mounted ball valves may require replacement if it becomes worn or damaged. This is important to ensure proper sealing and prevent leakage. The packing should be replaced with the appropriate type and size, following the manufacturer’s guidelines.

-

Actuator Maintenance: If the trunnion mounted ball valve is equipped with an actuator, regular maintenance of the actuator is necessary. This includes checking the actuator’s condition, lubricating moving parts, and verifying proper operation.

-

Calibration and Testing: Periodic calibration and testing of trunnion mounted ball valves may be necessary to ensure accurate flow control and proper functioning. This can include checking the valve’s opening and closing torque, verifying the seat tightness, and conducting performance tests.

It is important to note that maintenance practices may vary depending on the specific valve design, application, and manufacturer’s recommendations. It is recommended to consult the valve manufacturer’s documentation and guidelines for detailed maintenance procedures specific to the trunnion mounted ball valve being used.

2. Diverse Product Lineup

LENOR offers a comprehensive range of valves and control systems, meticulously designed for optimal performance:

- DK-Slurry Knife Gate Valve: Designed to handle abrasive slurries with ease.

- DQ-Series Knife Gate Valve: Reliable isolation solutions for challenging environments.

- DS-Series Double Knife Gate Valve: Ensures tight shutoff and minimal maintenance.

- DT-Series Throughgoing Knife Gate Valve: Perfect for demanding applications.

- Floating Ball Valves: Versatile and dependable for various industries.

- Globe Control Valve: Precise control over flow rates and pressures.

- Lenor Z-Series Linear Actuators: Enhancing valve automation.

- Lenor Z-Series Quarter Turn Actuators: Ideal for quarter-turn applications.

3. Trusted Engineering Excellence

In the intricate world of industrial engineering, precision and reliability are paramount. Among the many components that make up this complex machinery, valves play a pivotal role, regulating the flow of fluids and gases with utmost efficiency. In this realm of exacting standards, LENOR Valve Range emerges as a beacon of excellence, renowned for its unwavering commitment to quality and innovation.

From the heart of manufacturing plants to the sprawling pipelines that traverse continents, LENOR valves stand as guardians of operational integrity, ensuring seamless performance in diverse industrial applications. What sets LENOR apart is not just its extensive product range, but the meticulous craftsmanship and engineering prowess that underpin every valve bearing its name.

One of the hallmarks of LENOR Valve Range is its adaptability to the most demanding environments. Whether it’s high-pressure systems in petrochemical refineries or the rigorous conditions of offshore drilling platforms, LENOR valves exhibit unparalleled resilience, withstanding extremes of temperature, pressure, and corrosive elements without compromise.

Behind this exceptional durability lies a rigorous process of design and testing, where LENOR engineers leave no stone unturned in pursuit of perfection. Each valve undergoes stringent quality checks, adhering to international standards to guarantee optimal performance and longevity. This unwavering dedication to quality has earned LENOR Valve Range the trust of industry leaders worldwide, cementing its reputation as a benchmark for excellence.

Yet, LENOR’s commitment to innovation extends beyond reliability alone. As industries evolve and technologies advance, LENOR continues to push the boundaries of what’s possible, introducing cutting-edge features and materials to enhance efficiency and safety. Whether it’s incorporating state-of-the-art materials for enhanced durability or integrating smart technology for remote monitoring and control, LENOR remains at the forefront of industrial valve innovation.

Moreover, LENOR understands that every industrial application is unique, with its own set of challenges and requirements. That’s why the company offers a comprehensive range of valve solutions, customizable to meet the specific needs of each customer. Whether it’s a bespoke design for a specialized application or a standard valve from their extensive catalogue, LENOR ensures that every product delivers peak performance and reliability.

In an era where industrial operations are increasingly scrutinized for their environmental impact, LENOR also takes pride in its commitment to sustainability. By optimizing processes and materials to minimize waste and energy consumption, LENOR contributes to a greener, more sustainable future, aligning with the evolving needs of responsible industries worldwide.

In conclusion, LENOR Valve Range stands as a testament to the marriage of industrial excellence and engineering ingenuity. Trusted by industry leaders and relied upon in the most critical of applications, LENOR valves exemplify the pinnacle of reliability, performance, and innovation. As industries continue to evolve, LENOR remains steadfast in its mission to elevate industrial excellence, setting new standards for reliability, efficiency, and sustainability in the global engineering landscape.

4. Nationwide Support

With offices strategically located in Sasolburg, Eastern Cape (Jeffreys Bay), and Kwazulu Natal (Richards Bay), KV Controls ensures local support for clients throughout South Africa and neighboring countries. Our ISO-certified safety practices and world-class service guarantee reliability.

Explore LENOR’s Range Today!

Discover the power of precision engineering with LENOR. Visit our website to explore the full range of LENOR valves and control systems. Elevate your operations with trusted solutions that redefine industrial excellence: LENOR Valve Range 🚀

KV Controls: A Leading Valve Supplier in South Africa

When it comes to superior valve solutions, KV Controls stands out as a top-tier provider in South Africa. With expertise spanning various industries, KV Controls delivers high-quality valves that enhance operational efficiency and reliability. Let’s delve into what makes KV Controls a leader in the field:

1. Industry Expertise

KV Controls caters to a diverse range of sectors, including:

- Chemical and Petrochemical: Offering valves that meet stringent safety and performance standards.

- Mining and Minerals: Providing robust solutions for mining applications.

- Pulp and Paper: Ensuring smooth operations in paper mills.

- Steel Industry: Delivering reliable valves for steel production.

- Power Generation: Supporting energy facilities with precision-engineered valves.

- Hydrogen Industry: Addressing the emerging hydrogen sector.

2. Superior Valve Solutions

A Symphony of Ingenuity and Engineering Excellence

At KV Controls, our valves are more than mere components; they are the harmonious blend of innovation, precision, and reliability. We extend an invitation to you, our esteemed partners, to immerse yourselves in the transformative power of our valve range—a realm where control and efficiency dance in perfect harmony.

To get in touch with KV Controls, you can reach out to us through the following channels:

1. Website: Visit our website at KV Controls for detailed information about their products, services, and contact details.

2. Email: You can email us directly at info@kvcontrols.co.za for inquiries, product specifications, or any other assistance.

3. Phone: Give us a call at +27 16 100 4592 to speak with our knowledgeable team and discuss your requirements.

4. Visit our Offices:

o Naledi Office: Located at 46 Mercury Street, Naledi Industrial Park, Sasolburg, 1947

o Kwazulu Natal Office (Richards Bay): Find us at Unit 16 Rhino Park, 81 Ceramic Curve, Alton, Richards Bay

Feel free to choose the most convenient option for your inquiries or visit their website for more details. 📞🌐