What Is the Difference Between a Segmented Ball Valve and a Globe Valve?

When selecting a control valve for industrial applications, two common options are the segmented ball valve and the globe valve. While both are widely used for flow control, they differ significantly in design, performance, efficiency, and application suitability.

Understanding these differences helps engineers, technicians, and plant operators choose the most appropriate valve for their specific process requirements.

Design Differences

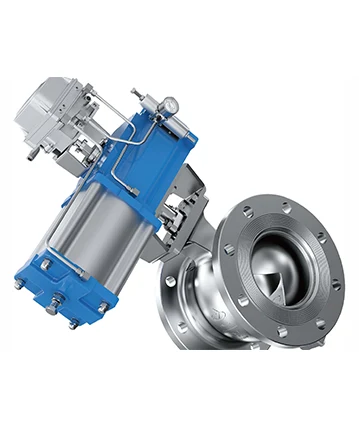

Segmented Ball Valve Design

A segmented ball valve features a V-shaped or partially cut ball (segment) that rotates 90 degrees (quarter-turn operation). This design allows for precise throttling and smooth flow modulation.

Key design characteristics:

-

Quarter-turn rotational movement

-

V-port segmented ball for controlled flow

-

Compact design

-

Typically paired with pneumatic or electric actuators

Globe Valve Design

A globe valve uses a linear motion mechanism, where a plug moves up and down to regulate flow through the valve seat.

Key design characteristics:

-

Linear movement (not rotational)

-

S-shaped internal flow path

-

Larger and heavier construction

-

Typically operated by manual handwheel or motorized actuator

Flow Control Performance

Segmented Ball Valve – Superior Throttling

Segmented ball valves provide excellent flow control, especially at low to medium flow rates. The V-shaped ball design allows for gradual and predictable flow changes, making them ideal for automated process control systems.

Advantages:

-

More accurate flow modulation

-

Lower pressure drop

-

Smooth and stable control

-

Suitable for slurries and viscous fluids

Globe Valve – Traditional Control Valve

Globe valves are also effective for throttling but generally cause higher pressure loss due to their internal flow path.

Characteristics:

-

Good flow control

-

Higher turbulence

-

Greater pressure drop

-

Better suited for clean fluids

Pressure Drop Comparison

One of the biggest differences between these two valves is pressure loss.

-

Segmented Ball Valve: Low pressure drop due to a more streamlined flow path.

-

Globe Valve: Higher pressure drop because the fluid must change direction inside the valve.

This makes segmented ball valves more energy-efficient in many applications.

Suitability for Different Media

Segmented Ball Valve Best For:

-

Slurries

-

Abrasive fluids

-

Viscous liquids

-

Gases and steam

-

Dirty or contaminated media

Globe Valve Best For:

-

Clean water

-

Steam control

-

Non-abrasive liquids

-

Applications requiring very fine control at low flow rates

Maintenance and Durability

Segmented Ball Valve

-

Lower maintenance requirements

-

Fewer internal parts subject to wear

-

More durable in harsh environments

Globe Valve

-

Requires more maintenance due to wear on seat and plug

-

More prone to leakage over time

-

Generally higher maintenance costs

Size and Installation

-

Segmented Ball Valve: More compact and lightweight, making installation easier.

-

Globe Valve: Bulkier and heavier, often requiring more space and structural support.

Which Valve Should You Choose?

Choose a segmented ball valve if you need:

-

Precise flow control

-

Low pressure drop

-

Better performance with slurries or dirty fluids

-

Automated control with actuators

Choose a globe valve if you need:

-

Very fine control at low flow rates

-

Reliable performance with clean fluids

-

Traditional control valve design

Conclusion

While both valves are effective in industrial flow control, segmented ball valves generally outperform globe valves in terms of efficiency, durability, and suitability for harsh media. Globe valves, however, remain a strong option for clean fluid applications requiring precise linear control.

Selecting the right valve depends on your specific application, media type, pressure conditions, and control requirements.

FREQUENTLY ASKED QUESTIONS (FAQ)

Q1: Which valve is better for throttling — segmented ball or globe?

A segmented ball valve is generally better for throttling in most industrial applications because it offers smoother control, lower pressure drop, and better performance with slurries and viscous fluids.

Q2: Does a globe valve last longer than a segmented ball valve?

Not necessarily. Globe valves tend to experience more wear due to their linear plug-and-seat design, while segmented ball valves are typically more durable and require less maintenance.

Q3: Can a segmented ball valve replace a globe valve?

In many applications, yes. Segmented ball valves can often replace globe valves, especially where lower pressure drop, better efficiency, and handling of dirty fluids are required.

READ MORE;

Segmented Ball Valves Explained

Uses of Segmented Ball Valves – kv control

ACTUATORS

ARC VALVES

BALL VALVE

BUTTERFLY VALVE

DESUPERHEATER

DIAPHRAGM VALVE

GLOBE CONTROL VALVE

GATE, GLOBE & CHECK

KNIFEGATE VALVE

PLUG VALVE

POSITIONERS

SAFETY VALVE

SEGMENTED BALL VALVE

SOLENOID VALVE