What is a Segmented Ball Valve and How Does It Work?

A segmented ball valve is a high-performance control valve designed for precise flow regulation in industrial piping systems. Unlike standard ball valves that mainly function as on/off valves, segmented ball valves are built specifically for throttling and modulating applications, making them essential in industries that require accurate and stable flow control.

These valves are widely used in industries such as water treatment, mining, chemical processing, power generation, pulp and paper, and oil and gas, where reliable and controlled fluid movement is critical.

What Makes a Segmented Ball Valve Different?

A segmented ball valve contains a V-shaped or partially cut ball (segment) instead of a full round ball. This design allows for much finer control over flow compared to traditional ball valves.

Key characteristics include:

-

Improved accuracy in flow regulation

-

Reduced turbulence and pressure drop

-

Better performance in high-pressure systems

-

Quarter-turn operation (90-degree rotation)

-

Compatibility with pneumatic or electric actuators

The segmented design enables smoother and more predictable flow changes, which is particularly important in automated process systems.

How Does a Segmented Ball Valve Work?

The operation of a segmented ball valve is based on controlled rotational movement:

1. Closed Position

In the fully closed position, the segmented ball blocks the flow passage completely, preventing any fluid from moving through the pipeline.

2. Initial Opening

As the actuator begins to rotate the valve stem, the V-shaped segment starts to create a small opening. This allows a controlled and gradual increase in flow.

3. Throttling Mode (Flow Control)

As the valve continues to open, the V-shaped segment progressively widens the flow passage. This provides precise modulation rather than sudden changes in flow rate.

4. Fully Open Position

At 90 degrees, the valve reaches full open position, allowing maximum flow with minimal restriction.

This controlled movement makes segmented ball valves ideal for applications that require smooth and adjustable flow rather than simple open/close functionality.

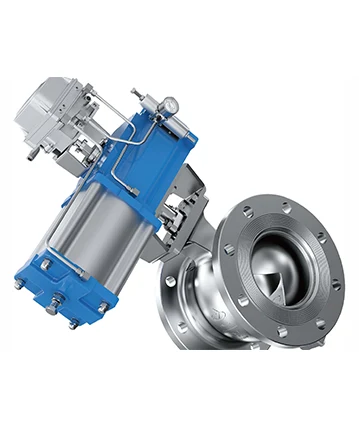

Key Components of a Segmented Ball Valve

A typical segmented ball valve assembly includes:

-

Segmented (V-Port) Ball – The main flow control element

-

Valve Body – Usually stainless steel or carbon steel for durability

-

Valve Seat – Ensures tight sealing when closed

-

Valve Stem (Shaft) – Connects the actuator to the ball

-

Actuator (Pneumatic or Electric) – Automates valve movement

-

Flanged Ends – Allows secure pipeline installation

Why Choose a Segmented Ball Valve?

Industries prefer segmented ball valves because they offer:

-

Superior flow control compared to standard ball valves

-

High durability in demanding environments

-

Lower maintenance requirements than globe valves

-

Better performance with slurries, gases, steam, and liquids

-

Reliable sealing and long service life

Common Applications of Segmented Ball Valves

Segmented ball valves are commonly used in:

-

Water and wastewater treatment plants

-

Mining and mineral processing operations

-

Chemical and petrochemical facilities

-

Power generation plants

-

Pulp and paper mills

-

Oil and gas pipelines

FREQUENTLY ASKED QUESTIONS (FAQ)

Q1: What is the main advantage of a segmented ball valve?

A segmented ball valve provides much better flow control than a standard ball valve because of its V-shaped (segmented) ball design, which allows precise throttling rather than only full open or closed positions.

Q2: Can a segmented ball valve be used for slurry and dirty fluids?

Yes, segmented ball valves are well-suited for slurries, viscous fluids, and dirty media because their design reduces clogging and allows smooth flow modulation compared to globe valves.

Q3: What type of actuator is best for a segmented ball valve?

Segmented ball valves can be operated with either pneumatic or electric actuators. Pneumatic actuators are commonly used in industrial process control due to their reliability, fast response, and suitability for hazardous environments.

Conclusion

A segmented ball valve is one of the most effective solutions for industrial flow control. Its unique V-shaped ball design provides excellent throttling capabilities, making it a preferred choice in many process industries.

For businesses looking for high-quality segmented ball valves, partnering with a trusted supplier ensures reliability, efficiency, and long-term performance.