REPAIR

CENTRE

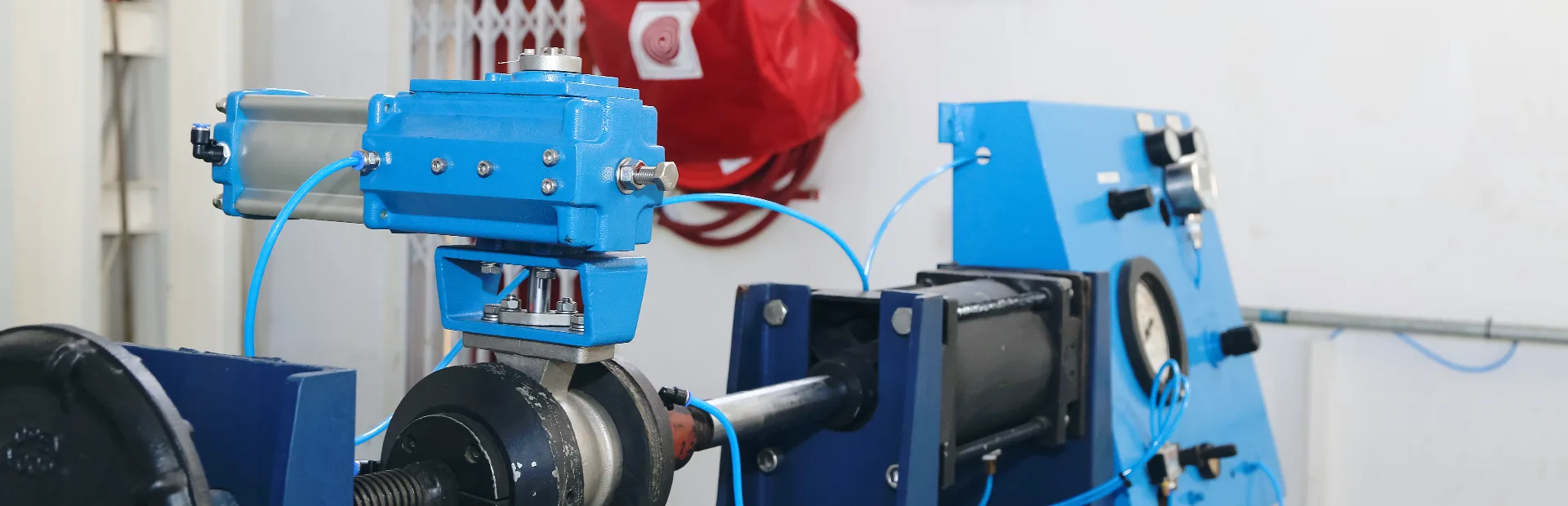

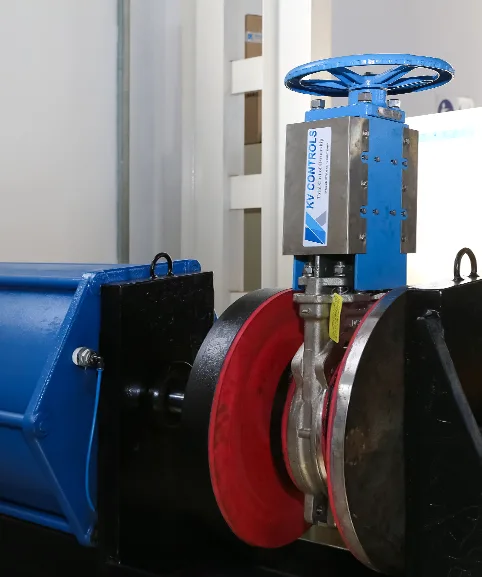

KV Controls has a fully equipped after sales service centre that enables us to do most engineering in house. The service centre offers the necessary equipment to increase our flexibility of excellent service. We boast a 15 ton overhead crane that enables us to handle and repair large size valves with ease.

We fully understand the need for excellent service and support for production plants. OEM parts are stocked in our regional warehouses.

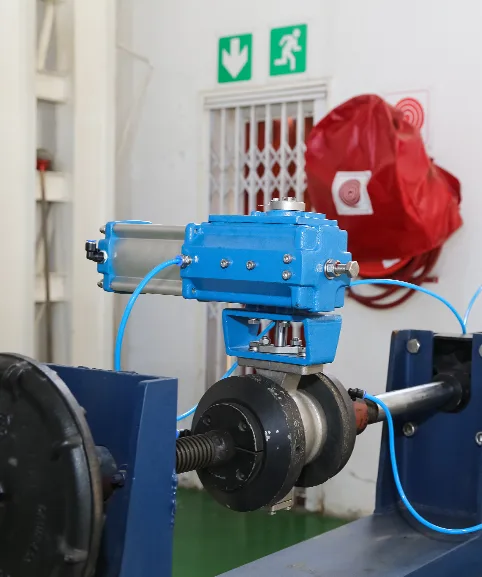

Valves are repaired to manufacturing standards and international codes of requirements for certified leakage and pressure tests. Control valves are calibrated, certified and tested.

All final testing is done to the appropriate international industry and plant standards.

Thinking globally but acting locally is part of KV Controls’ success.

We repair all valves to manufacturing standards and international code of requirements such as certified seat leakage and pressure tests.

Control valves calibration will be certified and tested.

Our works procedures forms party of our quality management system, ISO 45001:2018

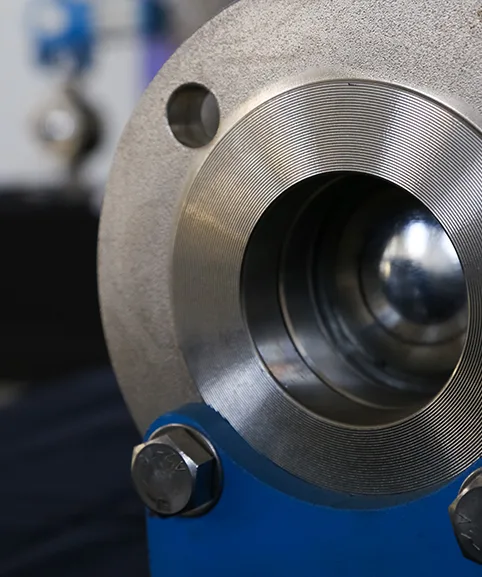

The seat leakage test requires a flow of water with a constant pressure. This enables us to measure the permissible leakage for all our different valve types.

Our seat leakage test rig can be used to test valves from DN50 to DN450. We also have capabilities and equipment to test even larger valves.

ENGINEERING SERVICES

KV Controls does all medium size engineering in-house, which gives us control over delivery times to our customers, and being able to cater for breakdowns after hours.

Our equipment range enables us to stock some undrilled valves and to drill to customer specification, to cater for various clients’ individual needs.

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023