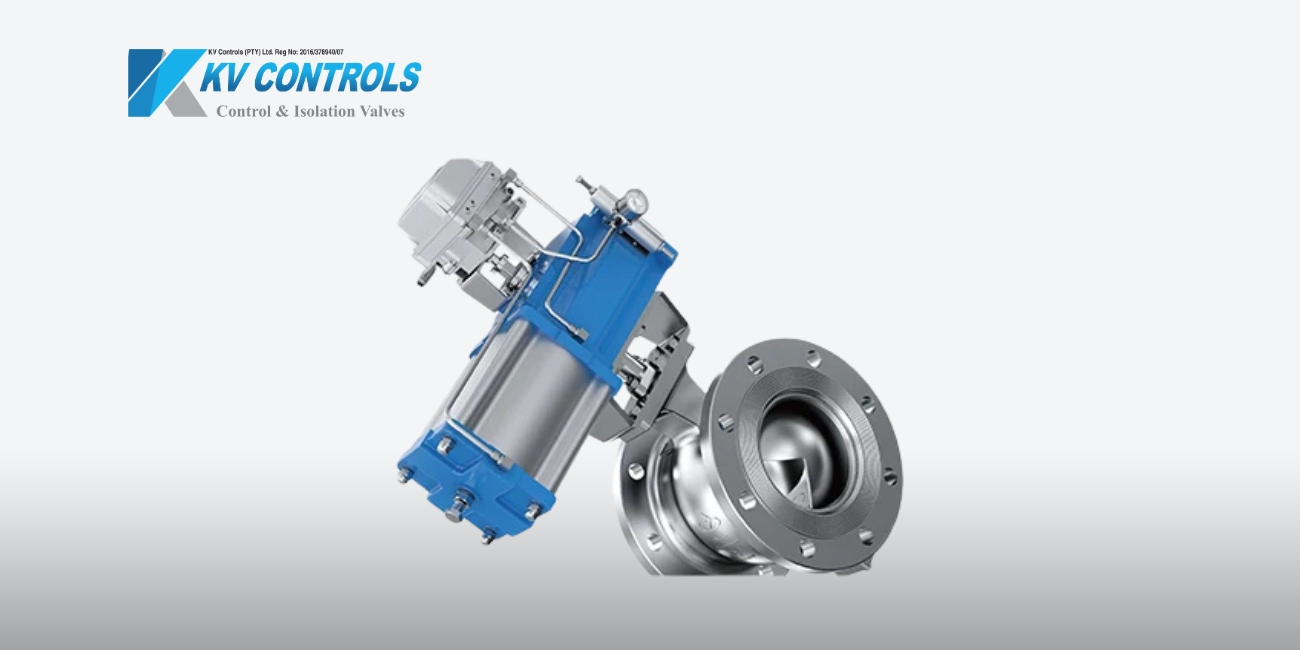

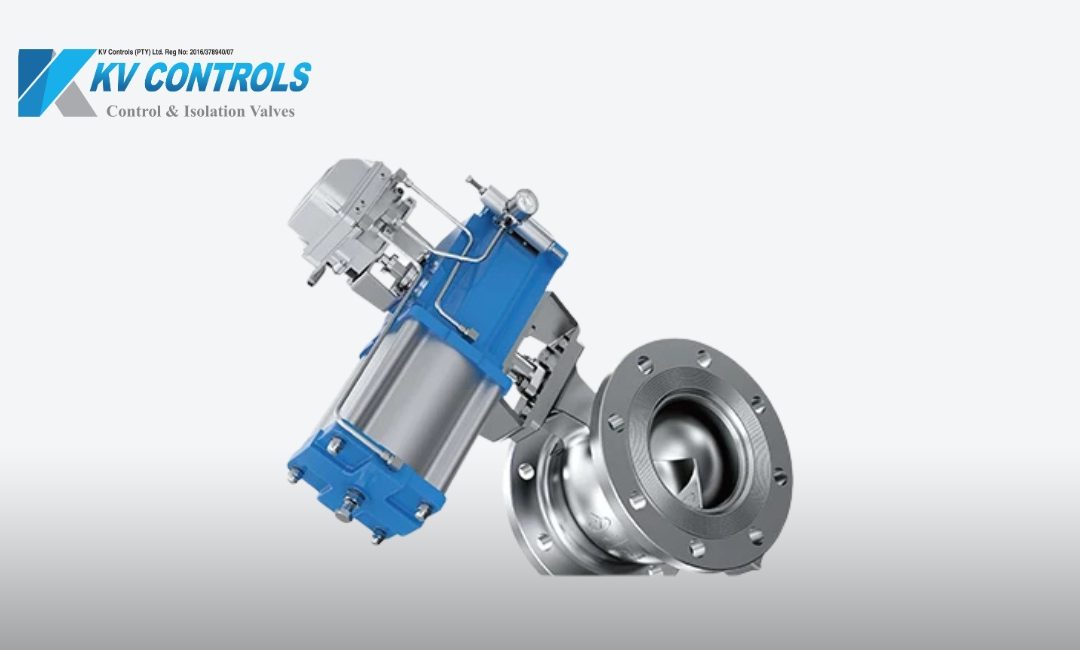

Precision Control with Segmented Ball Valves

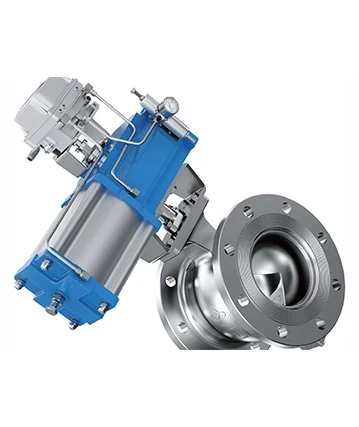

Segmented Ball Valves are designed for demanding throttle service, delivering exceptional flow control using a quarter-turn design. The RV Series, in particular, stands out for its reliable modulation and low torque operation—combining the control accuracy of a globe valve with the efficiency of a rotary ball valve.

These valves are essential for industries requiring precise flow regulation, such as pulp & paper, chemical processing, water treatment, and power generation.

What is a Segmented Ball Valve Used For?

Segmented ball valves are used primarily for modulating flow, rather than simple open/close operations. The RV Series features a V-notched ball that allows for accurate throttling, making it a preferred choice in systems where fine control and repeatability are critical.

Typical applications include:

-

Slurries and pulp stock in the pulp and paper industry

-

Corrosive or volatile chemicals in process plants

-

Variable flow conditions in water treatment facilities

How Does a Segmented Ball Valve Differ from a Traditional Ball Valve?

While traditional ball valves are known for simple on/off service, segmented ball valves like the RV Series are engineered for precise flow control. The key difference lies in the “V”-notched segment of the ball, which enables the valve to regulate flow with much greater accuracy.

Benefits of this design include:

-

Greater rangeability in control (often 100:1 or more)

-

Lower cavitation risk and reduced vibration

-

Smoother operation in dynamic systems

What is the Rangeability of the RV Series Segmented Ball Valve?

Rangeability refers to how well a valve can control flow across a wide range. The RV Series offers impressive rangeability, typically 100:1 or higher, allowing it to perform well at both low and high flow rates without compromising accuracy.

This makes it ideal for:

-

Batch processes where flow rates vary

-

Proportional control systems

-

Critical operations in chemical or thermal plants

Segmented Ball Valves

RV series is quarter turn control valve mainly recommended for throttle service, segment ball valve combines globe valve control with the efficiency of a rotary ball valve.

More Key Benefits of the RV Series:

-

✅ Low Operating Torque – Saves on actuator size and cost

-

✅ Tight Shut-Off – Offers both throttling and sealing in one valve

-

✅ Noise Reduction – Smooth flow prevents cavitation and wear

-

✅ Compact Build – Perfect for space-limited installations

Industries That Trust Segmented Ball Valves:

-

Pulp & Paper – Reliable performance with abrasive fluids

-

Chemical Processing – Resilient against harsh substances

-

Water & Wastewater – Adaptive control in changing conditions

-

Power Plants – Precision in high-pressure steam systems

-

Oil & Gas – Rugged design suited to upstream and downstream tasks

KV Controls: South Africa’s Preferred Supplier

At KV Controls, we offer a wide range of segmented ball valves—including the RV Series—backed by expert guidance and professional after-sales support. Whether you’re designing a new system or upgrading an existing one, we provide the right solution for reliable, efficient flow control.