MORE ABOUT

PNEUMATIC LINED GLOBE CONTROL VALVE

DESCRIPTION

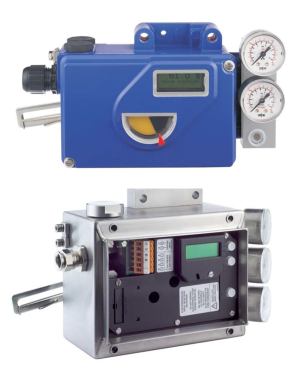

The pneumatic/electric lined single-seat control valve consists of many spring film actuators/electric actuators and through-way fluorine-lined single seat regulator. Installed on the medium pipeline and operated with other instrument to control parameters such as flow rate etc.

Due to the wetted parts of valve are lined with fluorine plastic (PTFE, PFA, FEP), and the stem sealing adopts PTFE bellow and packing, it has better performance in corrosion resistance and sealing and its installation has better reliability. It’s suitable for any corrosive medium except for “molten alkali metals and fluorine element”. The lined control valves are widely used in petrochemical, electric power, metallurgy, pulp & paper and other industrial automation device.

VIEW SPECIFICATIONS HERE

Exploring the Function of Pneumatic Lined Globe Control Valves

In the realm of industrial automation and fluid control, the pneumatic lined globe control valve stands out as a pivotal component. Renowned for its precision and reliability, this valve plays a critical role in various applications where fluid regulation is essential. But what exactly is a pneumatic lined globe control valve, and what are its primary functions? Let’s dive into its operation and benefits.

What is a Pneumatic Lined Globe Control Valve?

A pneumatic lined globe control valve is a type of control valve used to regulate the flow of fluids within a system. It combines the benefits of a globe valve’s throttling capabilities with the advantages of a pneumatic actuator and a corrosion-resistant lining. The globe valve design, characterized by a movable disc or plug and a stationary ring seat, is highly effective for controlling flow rates.

Key Components of a Pneumatic Lined Globe Control Valve

- Valve Body: Houses the internal components and is designed to withstand high pressure and temperature variations.

- Lining: The interior of the valve is lined with materials such as PTFE (Polytetrafluoroethylene) or other fluoropolymers, offering excellent resistance to corrosive fluids.

- Actuator: Pneumatically operated, the actuator provides the force needed to move the valve’s plug or disc. It converts air pressure into mechanical motion.

- Valve Plug/Disc: The movable part that controls fluid flow by varying the size of the opening through which the fluid passes.

- Seat: The stationary part of the valve against which the plug or disc seals to stop flow.

Functionality of Pneumatic Lined Globe Control Valves

The primary function of a pneumatic lined globe control valve is to modulate fluid flow and pressure within a system. Here’s how it operates:

-

Flow Regulation: By adjusting the position of the valve plug or disc, the valve can precisely control the flow rate. This modulation allows for fine-tuned control over the process fluid, essential in maintaining optimal operating conditions.

-

Pressure Control: The valve can maintain or adjust the pressure within a system by throttling the fluid flow. This ability is crucial in processes where consistent pressure is required to ensure product quality and system stability.

-

Corrosion Resistance: The lining inside the valve body protects it from corrosive fluids, extending the valve’s lifespan and ensuring reliable operation even in harsh chemical environments.

-

Automated Operation: The pneumatic actuator enables automated control, allowing the valve to respond quickly to changes in process conditions. This automation is vital for maintaining efficiency and safety in modern industrial systems.

-

Leak Prevention: The design of the globe valve, combined with the precision of the pneumatic actuator, ensures a tight seal when the valve is closed, minimizing the risk of leaks.

Applications of Pneumatic Lined Globe Control Valves

Given their robust design and precise control capabilities, pneumatic lined globe control valves are used in a variety of industries:

- Chemical Processing: For handling and regulating corrosive chemicals and maintaining precise process conditions.

- Pharmaceuticals: Ensuring accurate control of fluid flow in the production of medicines, where precision and cleanliness are paramount.

- Water Treatment: Managing the flow and pressure of treatment chemicals and water streams.

- Oil and Gas: Controlling the flow of hydrocarbons and other process fluids in refining and production operations.

- Food and Beverage: Regulating flow in processes that require strict hygiene and precise control.

Advantages of Pneumatic Lined Globe Control Valves

- Precision: Offers accurate control of flow and pressure, essential for maintaining process quality.

- Durability: The lining provides protection against corrosive fluids, enhancing the valve’s longevity.

- Reliability: Pneumatic actuators ensure consistent and responsive operation.

- Versatility: Suitable for a wide range of applications due to their robust construction and adaptability.

- Safety: Reduces the risk of leaks and ensures safe operation in hazardous environments.

Conclusion

Pneumatic lined globe control valves are indispensable in modern industrial applications, offering precise control, durability, and reliability. Their ability to handle corrosive fluids, automate operations, and maintain consistent flow and pressure makes them vital in industries ranging from chemical processing to pharmaceuticals and beyond. By investing in high-quality pneumatic lined globe control valves, businesses can ensure efficient, safe, and reliable fluid management in their operations.

LATEST PRODUCTS

INDUSTRIES

WE

SERVE

Chemical &

Petrochemical

Mining

Industry

Power

Generation

Pulp & Paper

Industry

Steel

Industry

Hydrogen

Industry

Water

Industry

Get in

Touch

KV Controls mission is world class prompt service with business integrity. Our Safety Management System is accredited (certified) to ISO 45001:2018.

OUR TRUSTED BRANDS

CONTACT

KV CONTROLS

Our head office is situated in Naledi Industrial Park in Sasolburg, South Africa. KV Controls also has offices in Eastern Cape (Jeffreys Bay) and Kwazulu Natal (Richards Bay). We have a network of distributors throughout South Africa and neighbouring countries, ensuring support right on your doorstep.

+27 16 100 4592

sales@kvcontrols.co.za

repairs@kvcontrols.co.za

FOLLOW US

Proudly designed by Bunnypants Graphic & Web Design Studio | 2023