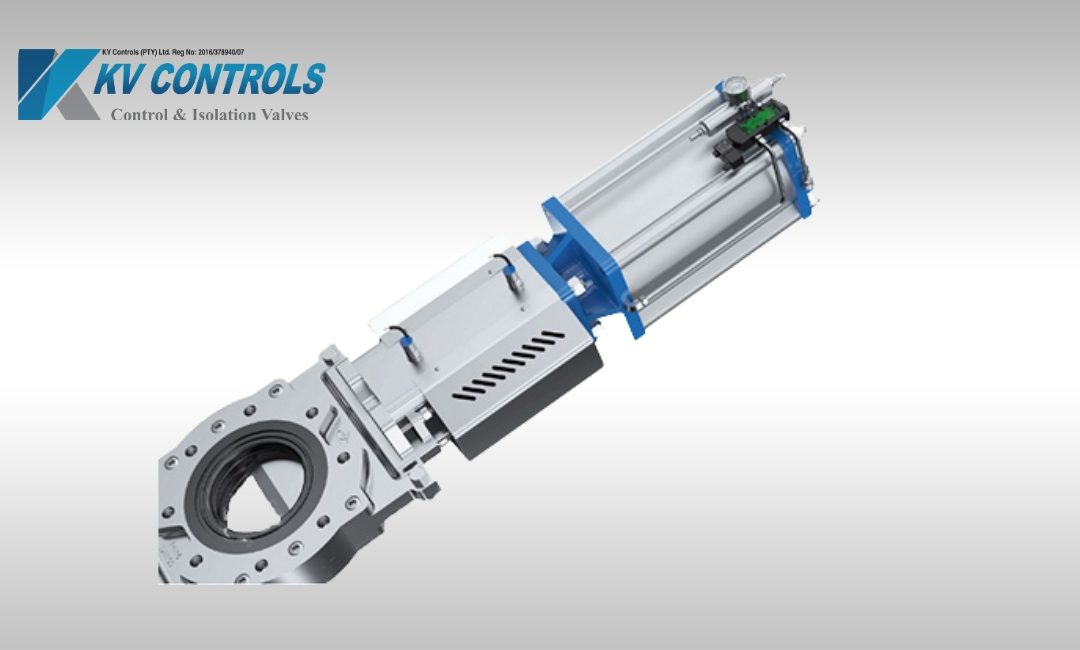

Precision Control with DK-Series Knife Gate Valves

At KV Controls, we supply cutting-edge flow control solutions built for performance, durability, and reliability in South Africa’s toughest industrial environments. Among our standout products, the DK-Series Knife Gate Valve continues to set the benchmark for managing abrasive and viscous media with exceptional ease and precision.

Whether you operate in mining, wastewater treatment, pulp and paper, or chemical processing, this valve offers the ultimate solution for demanding applications.

What Is a Knife Gate Valve?

The DK-Series Knife Gate Valve is designed to isolate or regulate the flow of materials such as slurry, sludge, and other particulate-heavy or corrosive fluids. The “knife” mechanism efficiently slices through dense or gritty media, ensuring smooth operation and minimal downtime.

Key Features of the DK-Series Valve

1. Rugged Construction

Made from stainless steel or cast iron, the DK-Series excels in corrosive and abrasive environments. It’s built to last in high-impact, high-pressure conditions.

2. Bi-Directional Sealing

Enjoy leak-proof performance in both directions, reducing the risk of backflow and enhancing system integrity.

3. Self-Cleaning Design

The self-cleaning gate reduces the buildup of debris, enhancing operational longevity and minimizing maintenance downtime.

4. Full Port Design

Allows unrestricted flow with minimal pressure loss, maximizing operational efficiency in high-volume applications.

5. Multiple Actuation Options

Choose from manual (handwheel or gearbox) or automated (pneumatic or electric) actuation to suit your specific control needs.

Where Can You Use the DK-Series?

Mining Industry

From slurry to dewatering, the valve handles abrasive materials with ease. Its robust build and self-cleaning function make it indispensable in mining.

Wastewater Treatment

Perfect for sludge control and grit removal, the DK-Series ensures reliability and leak-free operation in complex treatment systems.

Pulp and Paper

Handles high-consistency pulp, black liquor, and chemical dosing with controlled precision, ensuring uninterrupted flow in demanding environments.

Chemical Processing

Resistant to corrosion and chemicals, the DK-Series supports safe and efficient flow control in aggressive processing conditions.

Technical Specifications at a Glance

The DK-Series Knife Gate Valve is available in a size range from DN80 to DN800, with pressure ratings of PN10 to PN16 and ANSI 15 compatibility. It uses a wafer-type connection and supports a temperature range of -29°C to 100°C. The valve features a soft seat design with Leakage Class VI sealing, ensuring tight shutoff. Body material options include WCB, CF8, CF8M, and CF3M, allowing you to choose the best fit for your process environment.

Why Choose KV Controls for Your Knife Gate Valves?

At KV Controls, we go beyond supply—we offer engineered solutions tailored to your operation’s needs. The DK-Series Knife Gate Valve is a testament to our commitment to delivering high-performance, cost-effective, and low-maintenance flow control products.

Also explore our AOX Electric Actuators and Segmented Ball Valves for comprehensive flow control.

Talk to Our Experts

Ready to optimize your operations?

Contact us at sales@kvcontrols.co.za for expert guidance and personalized solutions.