In industries where precise steam control is vital, the Direct Steam Converting Valve – Steam Atomization (DSCV-SA) is a cornerstone of operational efficiency and safety. KV Controls is a trusted supplier of high-quality DSCV-SAs, tailored to meet the rigorous demands of modern power stations, steam distribution systems, and various industrial processes.

What is a DSCV-SA?

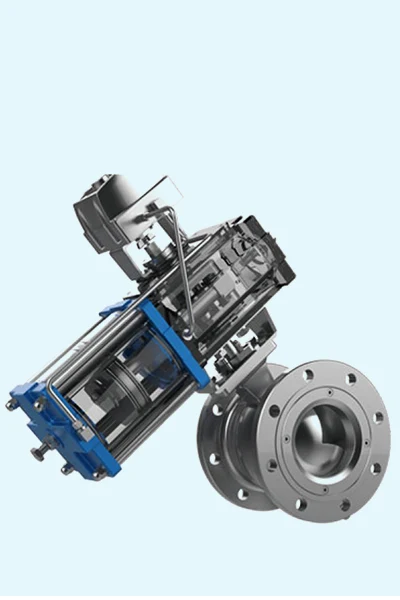

A Direct Steam Converting Valve – Steam Atomization (DSCV-SA) is an advanced valve system designed to regulate steam flow and pressure in critical applications. Whether managing steam turbine bypass systems, controlling continuous steam letdown stations, or supporting Combined Heat and Power (CHP) plants, this valve ensures reliability, safety, and efficiency.

How Does the DSCV-SA Work?

Engineered for precision, the DSCV-SA offers unparalleled control during essential plant operations, including start-ups, shutdowns, and turbine trips. Its innovative design eliminates risks associated with steam regulation, such as thermal shocks, ensuring long-term system stability.

Key features of the DSCV-SA include:

- Tight Shut-Off: Prevents steam leakage, preserving energy and system integrity.

- Thermal Shock Prevention: Reduces stress on equipment, extending its lifespan.

- Customizable Designs:

- Fully Rated or Split Rated: Optimized for various pressure and temperature requirements.

- Trim Technologies: Engineered to meet specific noise level needs, ensuring a quieter operation.

- Connection Flexibility: Available in flanged or butt-welded designs to suit customer preferences.

Why is the DSCV-SA Critical?

The DSCV-SA is not just a valve; it’s a solution designed to safeguard your operations. By maintaining precise steam control, it prevents system inefficiencies and operational hazards. This makes it a vital component for ensuring productivity and safety in high-stakes environments.

Applications of the DSCV-SA

The DSCV-SA’s versatility makes it indispensable across a wide range of industries, including:

- Power Generation: Supporting steam turbine bypass systems and heat recovery.

- Chemical and Petrochemical: Regulating steam in complex chemical processes.

- Pulp and Paper: Enhancing energy efficiency in production processes.

- Food and Beverage: Ensuring consistent steam flow for sterilization and cooking.

- Oil Refining: Managing steam distribution in refining processes.

- Sugar Refining: Maintaining precise temperatures for sugar production.

- Heat Supply Stations and Textiles: Providing reliable steam flow for heating and processing needs.

The KV Controls Advantage

At KV Controls, we understand that industrial operations demand reliability, precision, and efficiency. That’s why we supply Direct Steam Converting Valves – Steam Atomization that are engineered to exceed expectations. Our products are built to withstand high temperatures and pressures, ensuring seamless integration into your systems.

Our commitment to quality doesn’t stop at the product. We offer exceptional customer service, helping you select the right valve for your needs and providing ongoing support to ensure optimal performance.

Why Choose KV Controls?

- Unmatched Expertise: Decades of experience in steam control systems.

- High-Quality Products: We only supply valves designed for maximum reliability and performance.

- Tailored Solutions: Customizable options to meet the unique demands of your industry.

- Comprehensive Support: From selection to installation and maintenance, we’re with you every step of the way.

Conclusion:

The Direct Steam Converting Valve – Steam Atomization (DSCV-SA) is more than a valve—it’s a vital tool for achieving operational excellence. With its innovative features and wide range of applications, it ensures the safe, efficient, and reliable regulation of steam in industrial systems.

Let KV Controls be your partner in optimizing steam distribution and improving operational safety. Contact us today to learn how our DSCV-SAs can elevate your systems to the next level.