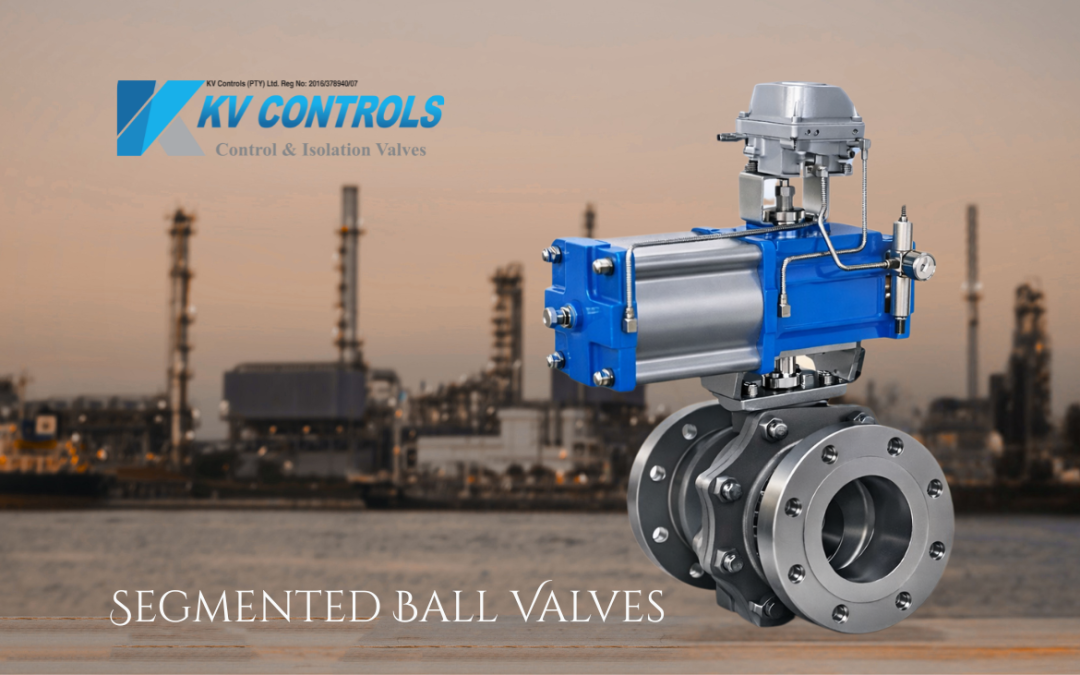

What Is a Segmented Ball Valve Used For in Industrial Applications?

A segmented ball valve is widely used in industrial applications that require precise flow control, reliability, and durability. Unlike standard ball valves that mainly function as on/off valves, segmented ball valves are specifically designed for throttling and modulating flow, making them ideal for complex process systems across multiple industries.

Their unique V-shaped segmented ball design allows for smoother flow regulation, reduced turbulence, and improved control accuracy, which is why they are commonly found in critical industrial operations.

Why Are Segmented Ball Valves Used in Industry?

Industries use segmented ball valves because they offer several key advantages:

-

Accurate flow control for automated systems

-

High-pressure handling capability

-

Resistance to wear and corrosion

-

Reliable performance in harsh environments

-

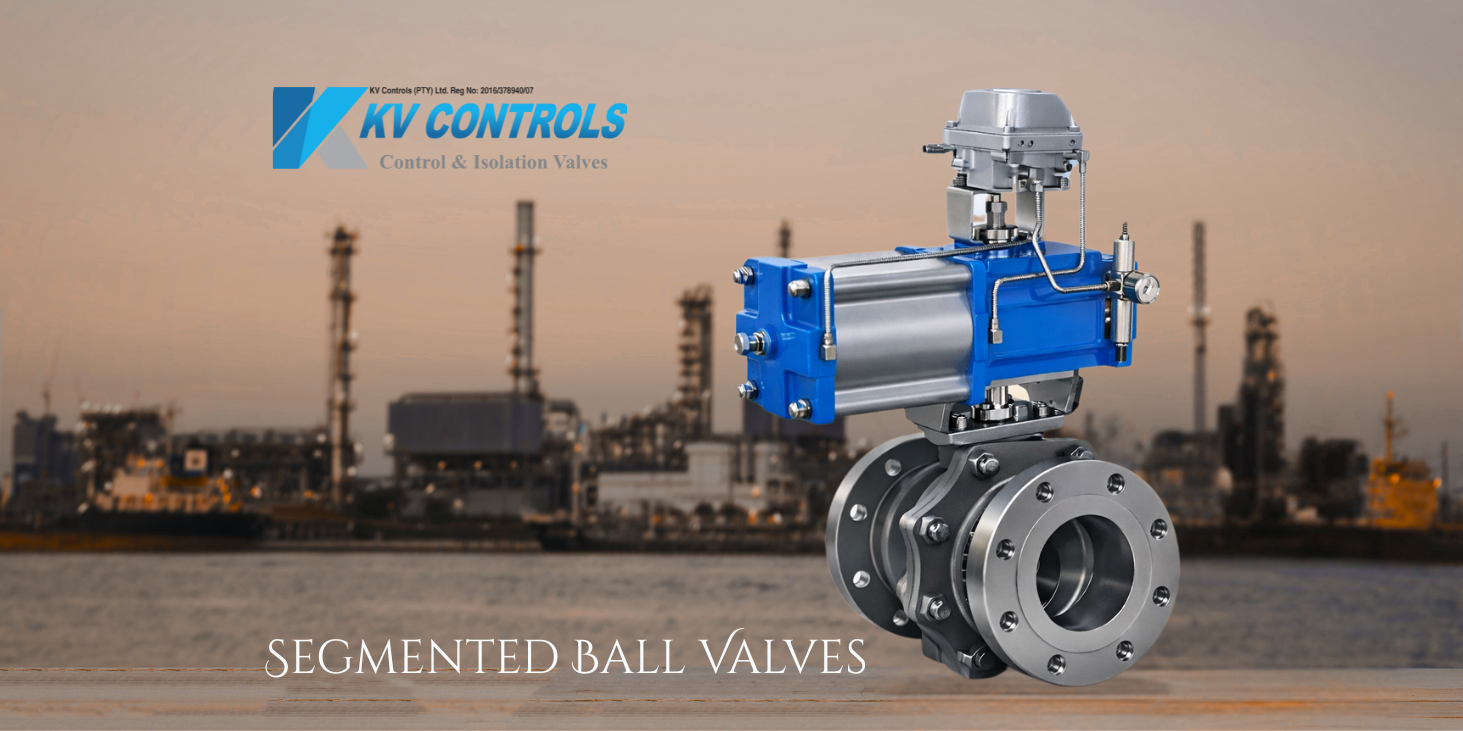

Compatibility with pneumatic and electric actuators

These features make segmented ball valves a preferred choice over globe valves and traditional ball valves in many applications.

Key Industrial Applications of Segmented Ball Valves

1. Water and Wastewater Treatment

In water treatment plants, segmented ball valves are used to control the flow of clean water, sewage, and chemical dosing systems. Their ability to handle slurries and contaminated fluids makes them highly effective in this sector.

Common uses include:

-

Pump control

-

Filtration systems

-

Chemical injection processes

-

Flow regulation in treatment pipelines

2. Mining and Mineral Processing

Mining operations rely on segmented ball valves to control the movement of abrasive slurries, chemicals, and high-pressure fluids. Their robust construction ensures long service life even in extreme conditions.

Applications include:

-

Slurry transport systems

-

Ore processing plants

-

Tailings management

-

Hydraulic flow control

3. Chemical and Petrochemical Industry

In chemical processing plants, precise control over fluid flow is essential for safety and efficiency. Segmented ball valves are used to regulate chemicals, gases, and steam in complex systems.

Typical uses include:

-

Reactor flow control

-

Pipeline distribution systems

-

Pressure regulation

-

Automated process control

4. Power Generation Plants

Power plants use segmented ball valves in cooling systems, steam control lines, and fuel supply systems. Their ability to operate reliably under high temperature and pressure makes them ideal for energy production facilities.

Common uses include:

-

Boiler feed systems

-

Cooling water circulation

-

Steam flow regulation

-

Turbine control systems

5. Pulp and Paper Industry

In pulp and paper mills, segmented ball valves help control the flow of pulp slurry, chemicals, and wastewater. Their design minimizes clogging and improves process efficiency.

Uses include:

-

Pulp flow regulation

-

Chemical mixing control

-

Wastewater management

-

Bleaching process control

Why Choose a Segmented Ball Valve for Industrial Use?

Segmented ball valves are chosen over other valve types because they provide:

-

Better control than standard ball valves

-

More durability than globe valves

-

Lower maintenance costs

-

Improved efficiency in automated systems

-

Strong resistance to abrasive and corrosive media

Conclusion

Segmented ball valves play a critical role in modern industrial operations by providing precise, reliable, and efficient flow control. Their versatility makes them suitable for a wide range of applications, from water treatment to mining, chemical processing, and power generation.

Selecting the right segmented ball valve and actuator combination is essential for optimal system performance and long-term reliability.

FREQUENTLY ASKED QUESTIONS (FAQ)

Q1: What industries benefit most from segmented ball valves?

Industries such as water treatment, mining, chemical processing, power generation, and pulp and paper benefit the most because they require precise flow control in demanding environments.

Q2: Can segmented ball valves handle high pressure?

Yes, segmented ball valves are designed for high-pressure applications and are commonly used in pipelines and industrial process systems that operate under extreme conditions.

Q3: Are segmented ball valves suitable for dirty or abrasive fluids?

Yes, their robust design and smooth flow path make them highly effective for slurries, viscous fluids, and abrasive media without frequent clogging or damage.

READ MORE;

Segmented Ball Valves Explained

ACTUATORS

ARC VALVES

BALL VALVE

BUTTERFLY VALVE

DESUPERHEATER

DIAPHRAGM VALVE

GLOBE CONTROL VALVE

GATE, GLOBE & CHECK

KNIFEGATE VALVE

PLUG VALVE

POSITIONERS

SAFETY VALVE

SEGMENTED BALL VALVE

SOLENOID VALVE